The recycling of lithium-ion batteries is crucial for both environmental sustainability and economic benefits. As the demand for electric vehicles and portable electronics grows, so does the need for efficient recycling processes. This article explores the steps involved in recycling lithium-ion batteries and highlights the opportunities for setting up a battery recycling plant in India.

The Recycling Lithium Ion Batteries Process

1. Collection and Pre-Treatment

Collection: Spent lithium-ion batteries are collected from various sources such as electronic waste centers and automotive dealerships.

Pre-Treatment: The batteries are then sorted and disassembled to separate the different components, including the cathode, anode, electrolyte, and casing.

2. Mechanical Processing

Shredding and Crushing: The disassembled components are shredded and crushed to increase the surface area, facilitating better chemical reactions.

Magnetic Separation: Magnetic separators are used to remove ferrous materials, leaving behind non-ferrous materials like lithium, cobalt, and nickel.

3. Chemical Leaching

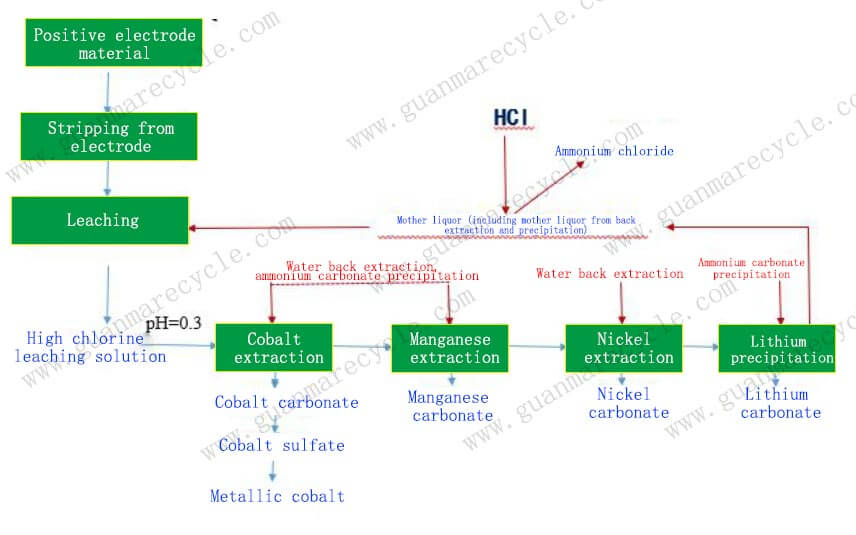

Leaching: The crushed material is treated with chemical reagents, such as sulfuric acid or sodium hydroxide, to dissolve the metal ions.

Filtration: The leachate is filtered to remove impurities and concentrate the metal ions.

4. Metal Recovery

Ion Exchange: Ion exchange resins are used to selectively adsorb the metal ions, separating them from the solution.

Precipitation: The metal ions are then precipitated out of the solution using chemical reagents, forming metal salts or oxides.

Electrowinning: For some metals, electrowinning is employed to deposit pure metal onto a cathode.

Benefits of Recycling Lithium-Ion Batteries

High Recovery Rates: The recycling process can achieve recovery rates of valuable metals like lithium, cobalt, and nickel, often exceeding 90%.

Environmental Sustainability: Recycling reduces the need for primary mining, minimizes environmental pollution, and prevents the disposal of hazardous waste.

Economic Value: The recovered metals can be sold back into the market, creating a circular economy and generating significant economic value.

Setting Up a Battery Recycling Plant in India

1. Market Potential

Growing Demand: India has a rapidly growing market for electric vehicles and portable electronics, creating a significant demand for lithium-ion batteries and their recycling.

Government Support: The Indian government offers various incentives and policies to promote the establishment of battery recycling plants.

2. Equipment and Costs

Recycling Machines: High-quality lithium battery recycling machines are essential for efficient processing. The price of these machines can vary depending on the scale and technology used.

Plant Setup: Establishing a battery recycling plant in India involves initial investments in equipment, infrastructure, and skilled labor.

3. Regulatory Compliance

Environmental Standards: Ensure compliance with local and national environmental regulations to avoid legal issues and maintain a positive reputation.

Safety Measures: Implement strict safety protocols to protect workers and the environment during the recycling process.

Recycling lithium-ion batteries is a vital process that combines environmental sustainability with economic benefits. By understanding the recycling process and the opportunities in India, you can take advantage of the growing market and contribute to a greener future. For more information on lithium battery recycling machines, plant setup, and regulatory compliance, feel free to contact us. Our team of experts is ready to provide comprehensive support and tailor a solution that meets your specific needs.