Home » Precious Metal Electrolytic Recovery Machine

Precious Metal Electrolytic Recovery Machine

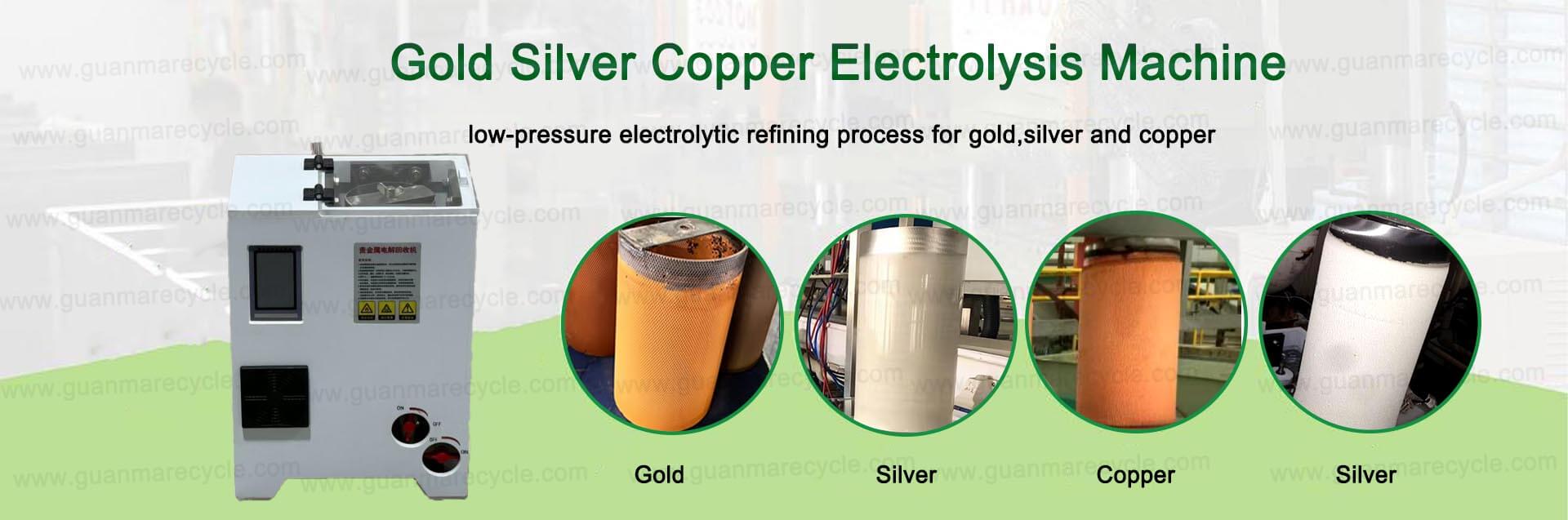

The Automatic Precious Metal Electrolytic Recovery Machine is a cutting-edge solution designed for the efficient and high-precision recovery of precious metals such as gold, silver, copper, and other valuable materials.

Product Description

The precious metal electrolytic recovery machine focus on recovering gold,silver,copper, nickel, tin,platinum, palladium and rhodium in the electroplating solution. The recovery rate reaches over 99%, and gold and other precious metals with a purity of over 95~99.8% can be directly extracted.

Raw Materials

The machine is engineered to recover precious metals from a wide variety of raw materials, copper ore, gold-plated plate, CPU, circuit board, It is particularly effective for processing electroplating solutions, circuit board stripping solutions, and other waste streams containing precious metals.

Final Product

The precious metal recovery electrolysis process yields pure, After processing, the machine produces refined gold, silver, and copper metals that meet industry standards for purity.

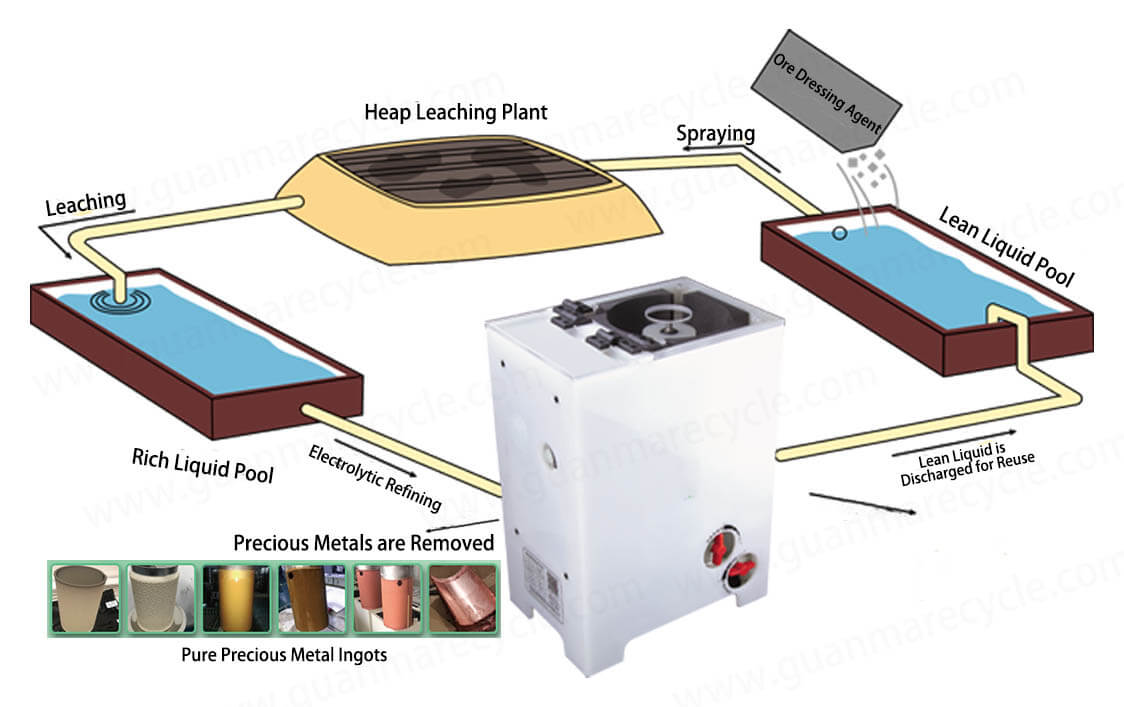

Flow Chart

The precious metal electrolytic recovery systems utilize a highly efficient electrolysis process. Through this system, precious metals are extracted from solutions using electricity, which causes the metals to migrate and settle onto electrodes. The principle of electrolysis is used to reduce precious metal ions in the liquid into metal blocks and adsorb them to the cathode barrel, thereby recovering high-purity gold and silver from the liquid.The process is fully automated, ensuring consistent and optimal performance throughout the operation.

Product Advantages

1.Electrolytic Recycling: This machine uses rotating cathodes and high-frequency pulses for intelligent electrolytic recycling.

2.Recovery Rate: Up to 99% for gold, silver, and copper.

3. High Recovery Efficiency: This system boasts excellent recovery rates, capable of extracting even trace amounts of precious metals from plating solutions and waste streams.

4. Fully Automated Operation: The Automatic Precious Metal Electrolytic Recovery Machine reduces the need for manual intervention.

5. Wide Range of Applications: Suitable for recovering gold, silver, copper, and other precious metals from various types of waste, including electroplating, electronic scrap, and industrial by-products.

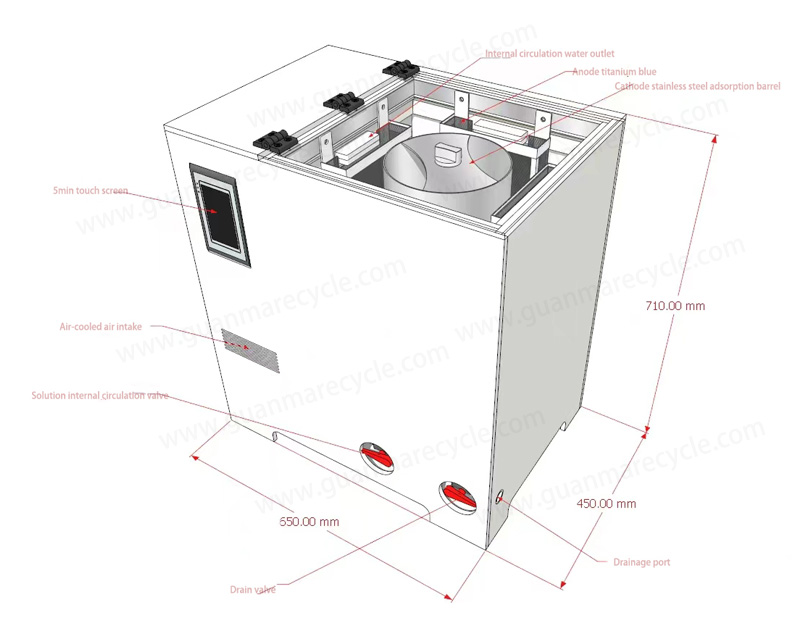

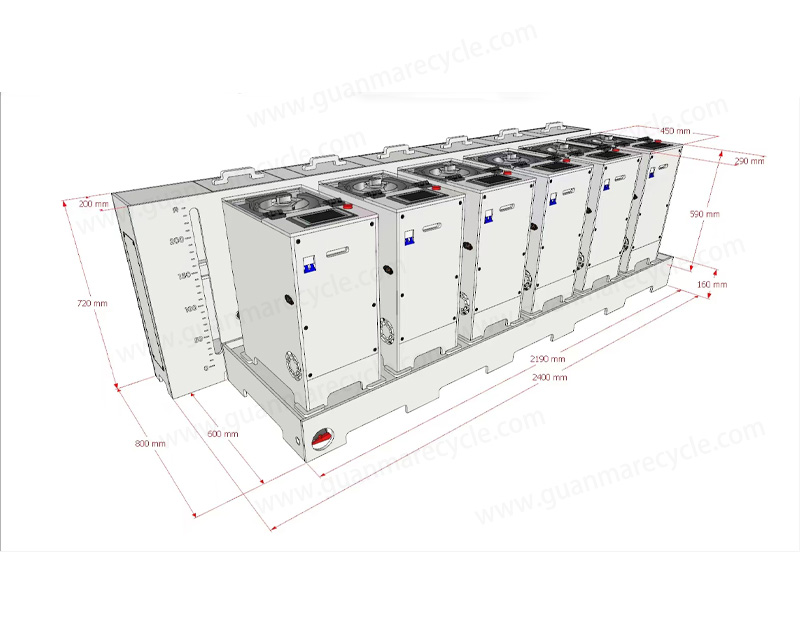

Technical Parameter

| Model | Capacity | Power | Rated Voltage | Size(Length*Width*Height) | Weight | Cathode Size |

| GM-101 | 1-3kg/day | 120W/h | 220V/50Hz | 710*650*450mm | 40kg | 159x310mm 219x365mm |

| GM-106 | 6-20kg/day | 720W/h | 220V/50Hz | 720*800*2400mm | 300kg | |

| GM-1010 | 20-50kg/day | 1200W/h | 380V/50Hz | 720*1600*2355mm | 450kg | |

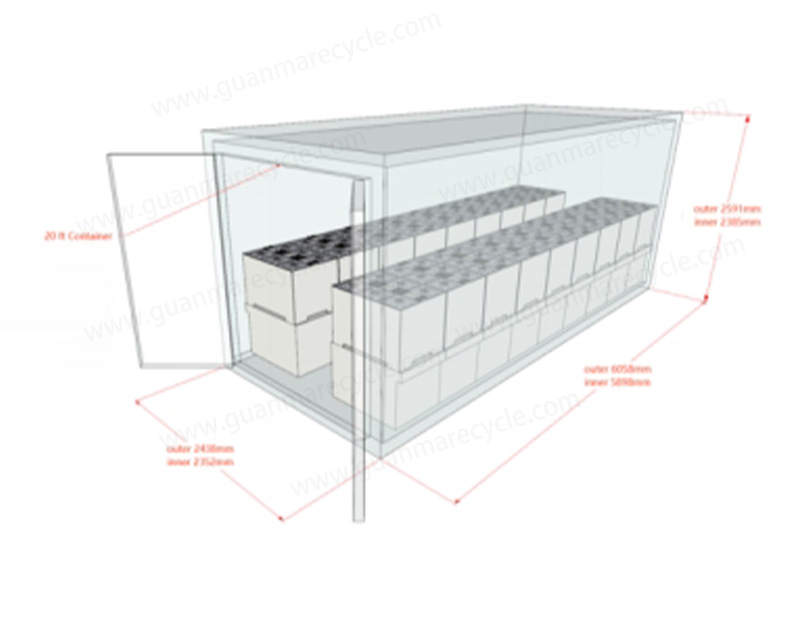

| GM-1084 | 100-500kg/day | 10080W/h | 380V/50Hz | 6000*2300*2300mm | 3780kg | |

| GM-10108 | 600-1000kg/day | 12960W/h | 380V/50Hz | 11800*2300*2300mm | 5000kg | |

| This table is for reference only, the actual parameters are subject to the quotation | ||||||

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)