Home » Precious Metal Extraction from Anode Sludge

Precious Metal Extraction from Anode Sludge

Precious metal extraction from anode sludge. Anode mud, the main valuable metals in anode mud are gold and silver, which are the raw materials for extracting gold and silver.

Product Description

Precious metal extraction from anode sludge. In the metallurgical process of copper, lead, antimony, thallium, tin, nickel and other metals, by-products containing precious metals are produced. Among them, copper, nickel, lead, antimony, tin and other crude metals are produced during the electrolytic refining process. Anode mud, the main valuable metals in anode mud are gold and silver, which are the raw materials for extracting gold and silver.

In addition to precious metals such as gold and silver, anode mud usually also contains Se, Te, Pb, Cu, Sb, As, Bi, Ni, Fe, Sn and mechanically mixed gangue such as SiO2, Al2O₃, etc., and its water content is Between 35% and 40%, the content of Sb and As in lead anode mud is higher than that of copper anode mud.

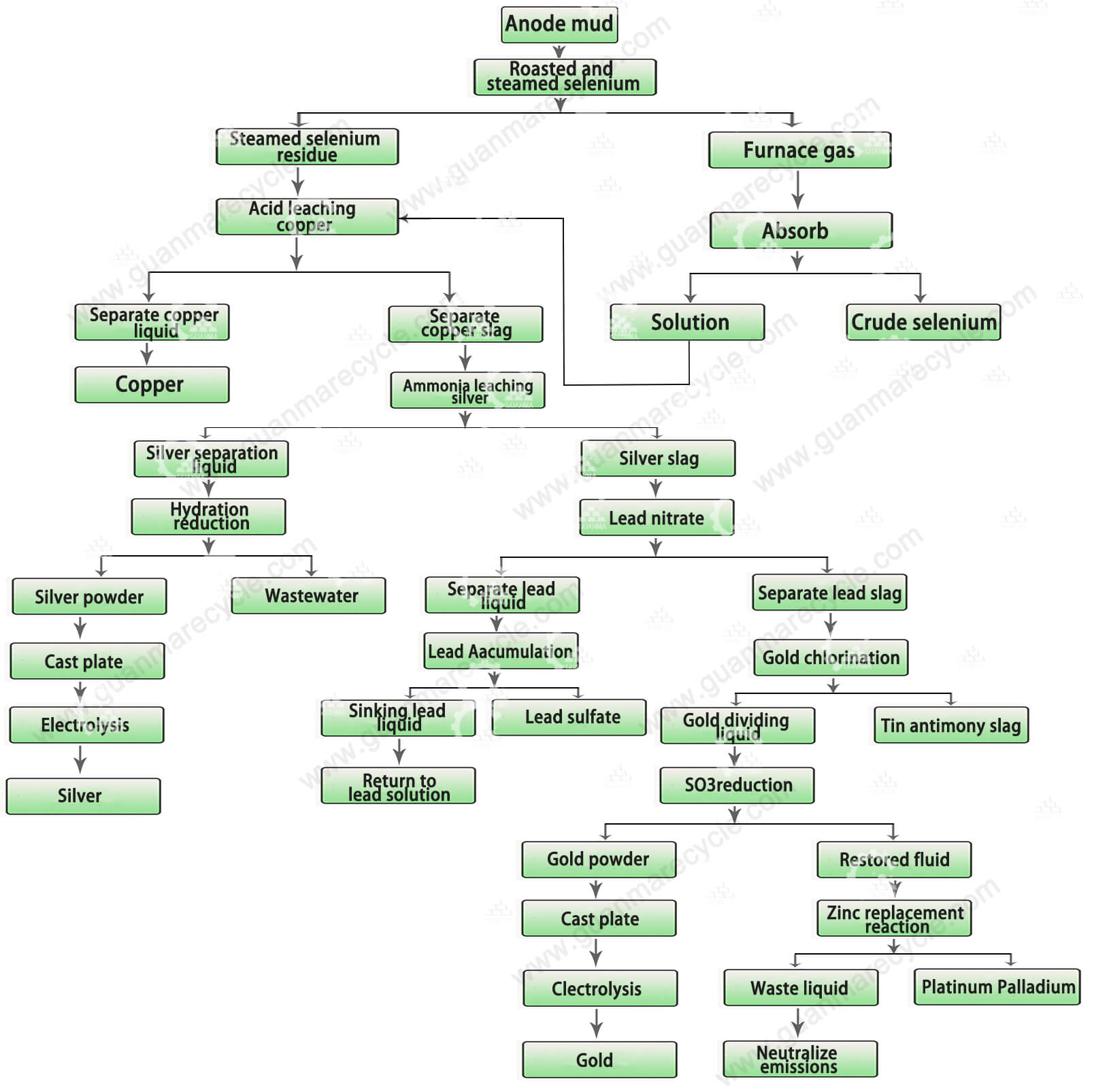

Flow Chart

The process of precious metal exaction from anode sludge is:

1. Removed copper and selenium: will roast and add acid to remove copper and seleium.

2. Separate silver: separate silver power from sliver separation liquid. After electrolysis will get silver.

3. Separate gold: separate gold power from sliver separation liquid. After electrolysis will get gold.

4. Recover platinum and palladium: after gold recovery, will use zinc to do replancement reaction to get platinum and palladium.

Product Advantages

1. The recovery rate of gold and silver is high, generally up to 97%~98%, and the highest can reach over 99%, which is higher than the traditional process.

2. Fewer steps and short process. It can produce high-quality gold or silver powder, which can be electrolytically refined after being melted and cast into anodes. No. 1 gold can be produced from the chlorinated leachate of gold by solvent extraction, completely eliminating the gold electrolysis process.

3. No intermediate recycling materials are produced. The wet process uses gold separation and silver separation processes to replace the smelting furnace and silver separation furnace in the fire process. It no longer produces intermediate recycling returns that account for 30% to 40% of the anode mud volume, which is beneficial to increasing the recovery rate and reducing costs. .

4. Good working conditions. The wet process eliminates the smelting furnace and silver separation furnace, which avoids the pollution of flue gas containing harmful elements such as lead and arsenic, and eliminates the need for corresponding dust collection and flue dust treatment system facilities and operations.

5. Good comprehensive utilization. During the separation process of base metals, the valuable metals in the anode mud are enriched in the slag or the solution with a high enrichment ratio, which can be comprehensively utilized more easily.

Technical Parameter

Precious Metal Extraction from Anode Sludge Technical Parameter

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity kg/day | Power/kw | Size(Length*Width*Height) | Project Budget(USD) |

| PGM-100 | 100-200kg | 300kw | 10000*5500*6000mm | 150000USD |

| PGM-300 | 300-500kg | 500kw | 15000*8500*6000mm | 200000USD |

| PGM-500 | 500-1000kg | 800kw | 20000*15000*7000mm | 500000USD |

| PGM-1000 | 1000-2000kg | 1000kw | 35000*20000*7000mm | 1000000USD |

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)