Home » Ternary Lithium Battery Extraction Equipment

Ternary Lithium Battery Extraction Equipment

The main processes of ternary lithium battery extraction equipment include pretreatment, cathode material processing, leaching and other processes. The purpose is to effectively separate the graphite, cathode material powder, copper, aluminum and steel shell from the calcined and crushed waste lithium batteries, thereby achieving resource utilization. Recycle effectively.

Product Description

Ternary Lithium Battery Extraction Equipment.The main purpose of this project is to verify the feasibility of the recycling process for waste ternary lithium batteries. Based on mainstream wet processes and integrating various advantages of physical and chemical methods, a solution based on environmental protection, low-carbon, and intelligence is proposed. The project provides solutions for pre-treatment lines, physical crushing and sorting lines, wet treatment lines, ternary precursor synthesis lines, and wastewater treatment lines.

Raw Material

Ternary lithium battery extraction equipment processes raw materials: Iron Can NCM_NCA, Negative Electrode, Mobile Battery, Positive Electrode, Iron Can LFP, Pouch, Pouch NCM_NCA, Laptop’s Battery

Iron Can NCM_NCA

Negative Electrode

Mobile Battery

Positive Electrode

Iron Can LFP

Pouch

Pouch NCM_NCA

Laptop's Battery

Final Product

Final Products:Manganese Sulfate, Nickel Sulfate, Cobalt Sulfate, Lithium Carbonate, Copper Sulfate, Cobalt Oxide, Positive Electrode Powder, Negative Electrode Powder, etc.

Manganese Sulfate

Nickel Sulfate

Cobalt Sulfate

Lithium Carbonate

Copper Sulfate

Cobalt Oxide

Positive Electrode Powder

Negative Electrode Powder

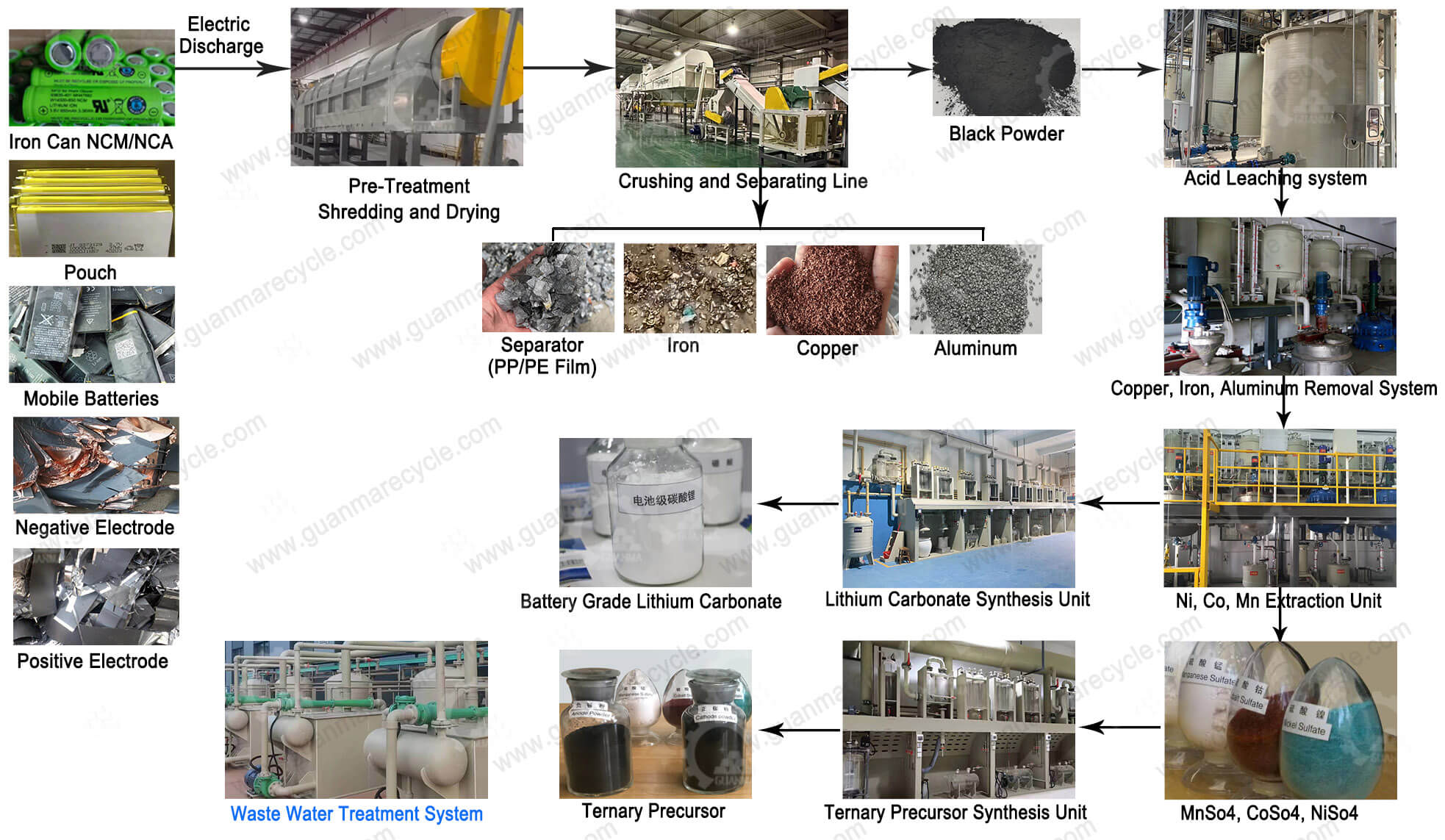

Flow Chart

This project adopts a process flow of pre-treatment leaching purification extraction concentration ternary precursor preparation. The main process for recovering valuable metals from waste lithium-ion batteries involves tearing, drying, rough crushing, drum sorting, two-stage magnetic separation, multi-stage vibration, and airflow density sorting to obtain mixed black powder. The black powder is then subjected to acid leaching, impurity removal, extraction, concentration, synthesis, and other processes to obtain products such as manganese sulfate, nickel sulfate, cobalt sulfate, lithium carbonate, and ternary precursor.

Product Advantages

1. Wet recycling technology can recycle more metal materials, especially for metal materials that are difficult to recycle and has unique advantages.

2. In the process of wet recovery, the required equipment and operations are relatively simple, easy to operate, and widely used.

3. Able to achieve higher metal recovery purity and lower energy consumption.

4.High safety: Battery wet recycling is already a very mature processing technology. It can effectively avoid harmful substances causing harm to operators during the operation, ensuring the safety of the entire process to a large extent.

Technical Parameter

Ternary Lithium Battery Extraction Equipment Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity tons/day | Power/kw | Size(Length*Width*Height) |

| LBE-50 | 50-60tons/day | 270kw | 45000*3500*6000mm |

| LBE-70 | 70-80tons/day | 300kw | 50000*4000*6000mm |

| LBE-100 | 90-100tons/day | 400kw | 55000*4500*6000mm |

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)