Home » PCB Dismantling Equipment

PCB Dismantling Equipment

PCB dismantling equipment is used to separate electronic components from various printed circuit boards, such as computer boards, mobile phone boards, TV boards, communication boards, etc. Our disassembly machine can completely dismantle high-value chips and CPUs, ensuring that the chips and CPUs are not damaged, allowing for secondary use and increasing economic value.

Product Description

PCB dismantling equipment (electronic component dismantling machine) is mainly used to dismantle the electronic component from PCB of computer, TV set, and other electrical application facility.

Compared with manual way, this dismantling equipment is automatical operation, high efficient, lowcost, small covering area, easy operation, and no dust pollution. The PCB after dismantled, called base board, can be recycled by physical methods to get copper and other non-metal material. The dismantling rate can be to achieve 95%.

Raw Material

PCB dismantling equipment is used to remove the electronic components on different PCB boards form discarded TV sets, tape recorders, computers, etc. On the one hand, impurities can be removed, and on the other hand, the electronic components can be recycled and reused.

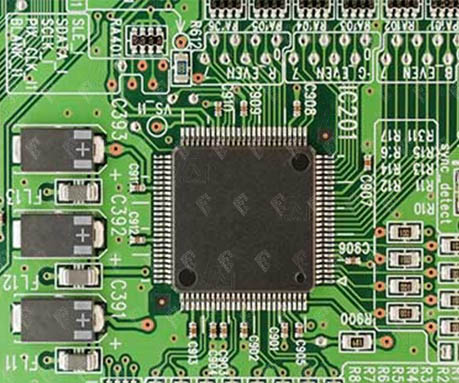

Computer Boards

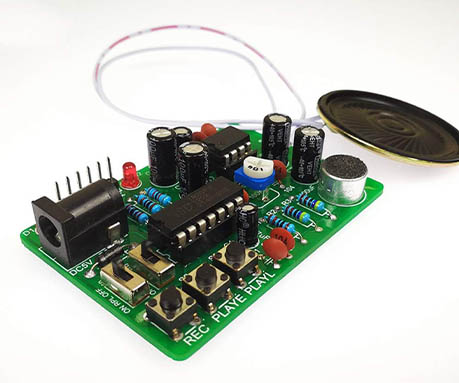

Phone Boards

Pure tin Circuit Board

Recorder circuit board

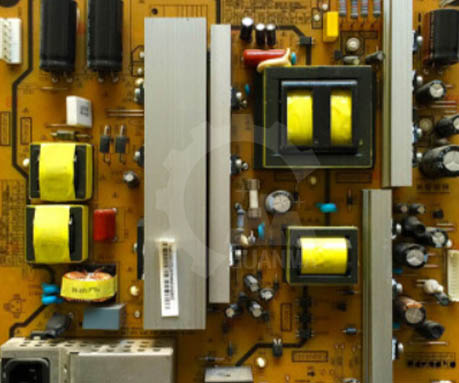

TV Board

Fridge Board

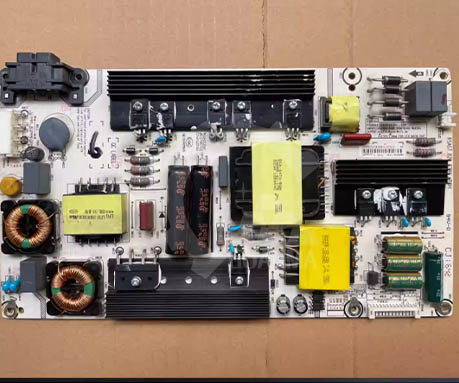

LED TV Board

Old TV Board

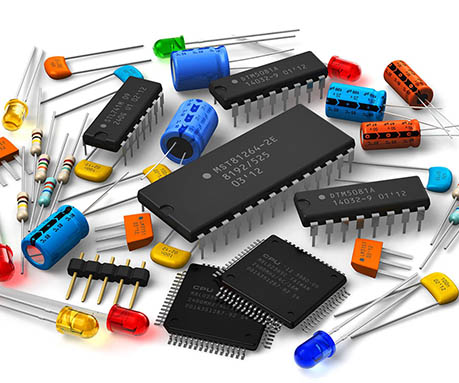

Final Product

The final products that can be disassembled by PCB disassembly equipment are: electronic components, CPU, capacitors and other components.

Electronic Components

CPU

Capacitance

Capacitance

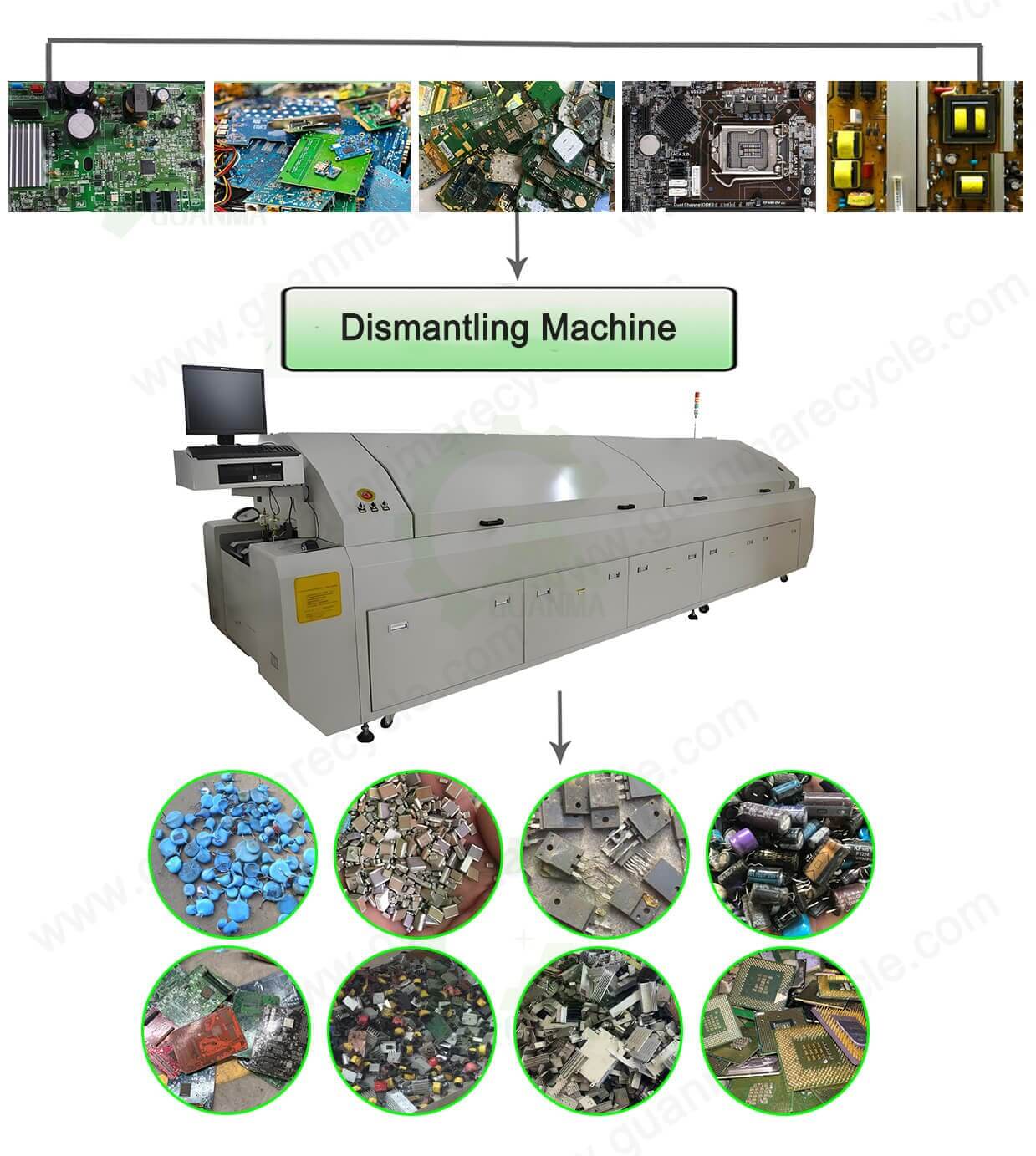

Flow Chart

Dismantling Machine is a single machine can remove electrostatic components. Then can do further process of motherboards, IC chips, MLCC, and so on.

Product Advantages

Unique advanced and long-lasting heating system

1. The heating system adopts high-efficiency and energy-saving Swedish nickel-iron heating tubes with a radiation power peak wavelength of 4UM. It is matched with a curved reflector, which has high thermal efficiency and fast temperature rise. The special forced hot air circulation structure system allows the PCB and components to be heated evenly and completely eliminates the problem of heat loss. “shadow effect”;

2. The insulation system adopts a special high-temperature resistant protection system, which is suitable for leaded and lead-free soldering.

3. Adopt Taiwan’s Sanyue long-axis high-temperature wind motor and W-shaped heating pipe design, modular design, no noise, no vibration, easy maintenance and disassembly;

4. The top and bottom of the furnace body are made of porous galvanized plates for uniform airflow, ensuring that the heat reaches the PCB evenly and balancedly. The upper furnace body can be opened as a whole to facilitate furnace cleaning.

Reliable and smooth transmission system

1. The transmission system adopts D speed regulating motor, matched with 1:60 turbine reducer, which ensures smooth operation and stepless adjustment of speed from 0 to 1200mm/min.

2. Using independent roller structure and flat support, combined with matching stainless steel mesh belt, it runs smoothly and the speed is accurate up to ±20mm/min;

3. Special stainless steel B-shaped mesh belt, durable and wear-resistant, not easily deformed after long-term use.

Stable and reliable electrical control system

1. The temperature control adopts RKC instrument control precision control system with fuzzy control and PID intelligent operation. Through PID intelligent operation, the heat is automatically controlled. The fuzzy control function adds overshoot and suppression functions and quickly responds to external heat changes. It is the fastest The temperature responds to changes in external heat and ensures a more balanced temperature through internal control;

2. Each temperature zone uses Taiwan Panduit thermocouples to quickly and sensitively respond to changes in each temperature zone, transmit and control in a timely manner, and compensate for the temperature balance of each temperature zone;

3. The special SSR solid state relay cooperates with the special radiator to greatly improve the heat dissipation efficiency and effectively extend its service life; it has no contact output, is safe and reliable, and combined with the unique fuzzy control function of the thermostat, it always monitors the external temperature and When the caloric value changes, the heating device is controlled with minimum pulses and responds quickly to ensure high temperature control accuracy, uniform temperature distribution within the machine, and lengthwise temperature distribution in compliance with IPC standards;

4. Plenty of power and rapid heating, from room temperature to constant temperature in about 20 minutes;

5. Equipped with temperature out-of-tolerance, fault diagnosis and optical alarm;

6. Delayed shutdown protection function, which cools down evenly after shutdown to prevent deformation of transmission components due to uneven cooling.

7. It has a power-off protection function to ensure that the PCB board outputs normally without being damaged after a power outage. (hand push type)

Technical Parameter

PCB Dismantling Equipment Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | DS-4435 | DS-6635 |

| Number of heating zones | Up 4 Down 4 | Up 6 Down 6 |

| Heating zone length | 1400mm | 2100mm |

| Heating method | Electricity | Electricity |

| Number of cooling zones | 1 | 2 |

| Belt width | 350mm | 350mm |

| Conveyor belt height | 880±20mm | 880±20mm |

| Transmission method | Network drive | Network drive |

| Conveyor belt speed | 0-1200mm/min electronic speed regulation | 0-600mm/min electronic speed regulation |

| Power supply | 3 phases 380V 50/60Hz(Voltage can be customized) | 3 phases 380V 50/60Hz(Voltage can be customized) |

| Starting power | 16KW | 24KW |

| Normal working power consumption | Approx.2.5KW | Approx.3.5KW |

| Heating time | About 20 minutes | About 20 minutes |

| Dimensions | L2600×W700×H1250MM | L3600×W700×H1350MM |

| Weight | Approx.300Kg | Approx.450Kg |

Case

Related Products

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)