Home » Fully-Automatic Tyre Recycling

Fully Automatic Tyre Recycling

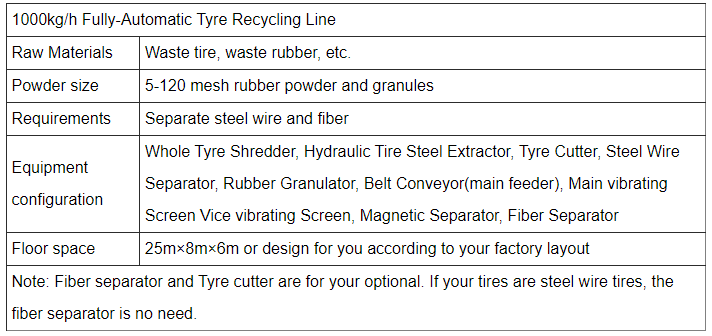

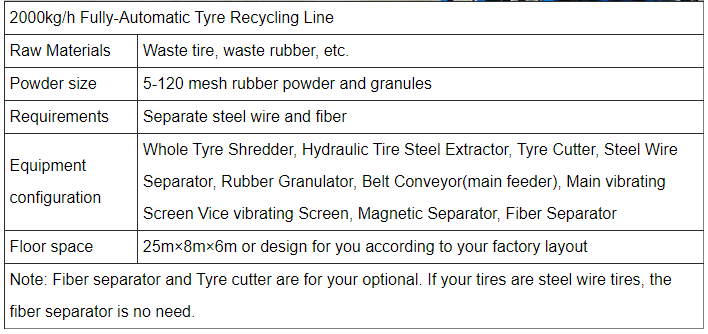

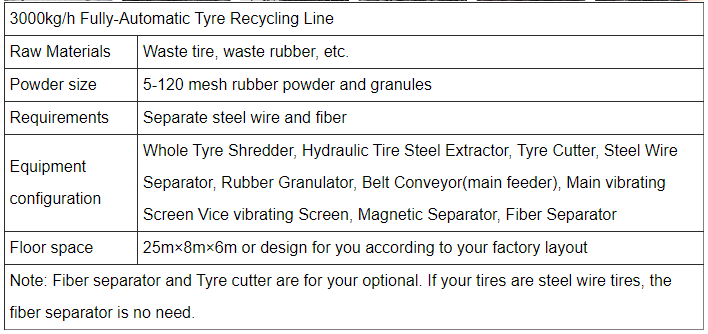

The fully automatic tire recycling line is used to process waste tires. The raw materials for waste tires include waste tires, waste inner tubes, waste tapes, waste rubber hoses, waste rubber shoes, etc., as well as waste products and scraps generated in the production process of rubber products. Belongs to a major category of industrial solid waste.

Product Description

The fully automatic tire recycling line is used to process waste tires.Waste tire resources mainly come from waste tires, waste inner tubes, waste tapes, waste rubber hoses, waste rubber shoes and other rubber products, which are industrial solid waste. In order to protect the environment and reduce the environmental pollution caused by waste rubber, it is very necessary to realize the recycling and reuse of waste rubber, especially waste tires. Currently, waste fully automatic tire recycling line can generally process 20-40 mesh rubber powder.

Raw Material

Common materials for scrap tires include:Bicycle tire,Motorcycle tire,Car tire,Truck tire,OTR tire,Other tires.

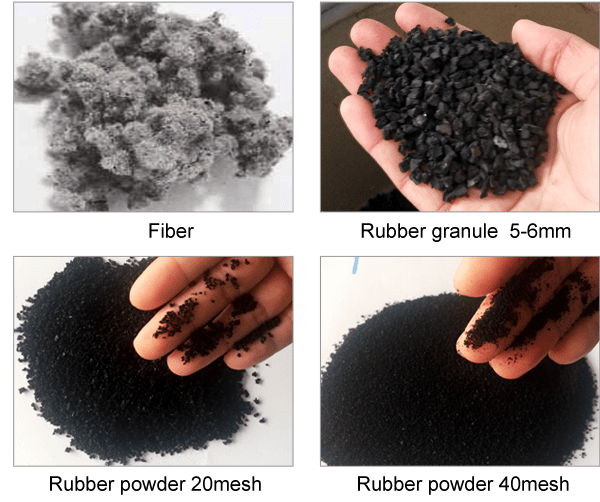

Final Product

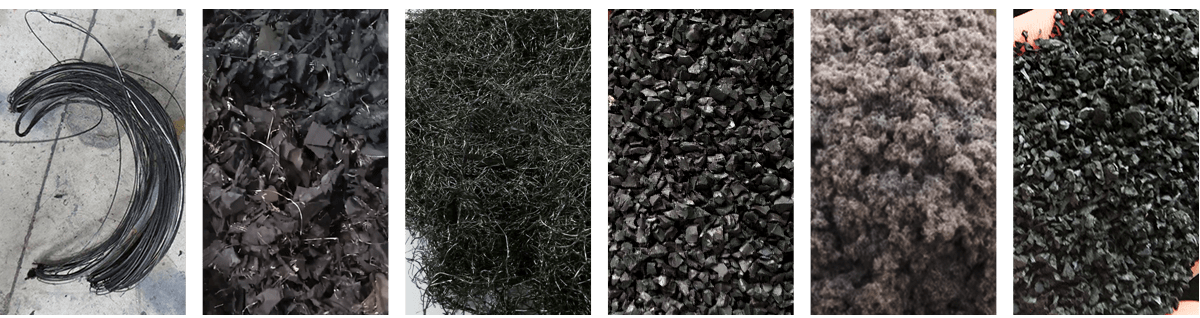

Final products: steel wire, fiber, rubber powder, rubber block, rubber granules, etc.

Flow Chart

1.Steel-extracting machine: The steel wire is separated from the tire pieces through hydraudic pressure mechanical power.

2.Rough shredder: The tyre which has been removed out the steel wire is shreded into blocks about 50mm-100mm.Then they are transported into medium shredder for further process by conveyor.

3.Meduim shredder: the function of the rough shredder is further cutting the tyre blocks into 10-20mm granules.

4.Magnetic separator: magnetic separator which is used for removing steel wire from discharge port of all medium shredders if there is any steel wire remaining in tire blocks or granules,it will separate the blocks again and returns them to smashing room and till wires are removed fully.Meanwhile it does not affect the fine shredder’s working.

5.Fine shredder: The new-brand explosion-proof structural design,uncreasingly inject the nitrogenduring the work process,because the temperature is increasing unceasingly.Simultaneously,this machine shredder the material to 3-5mm.

6.Double class powder grinder: grind 3-5mm granules into 40-80 mesh rubber powder.

7.Fiber separator: create air eddy and separate rubber granules from fiber then according to your requirements classify the rubber powder from 40 to 80 meshes.

8.Packing platform: realize packing as certain quality according to customer’s requirement.

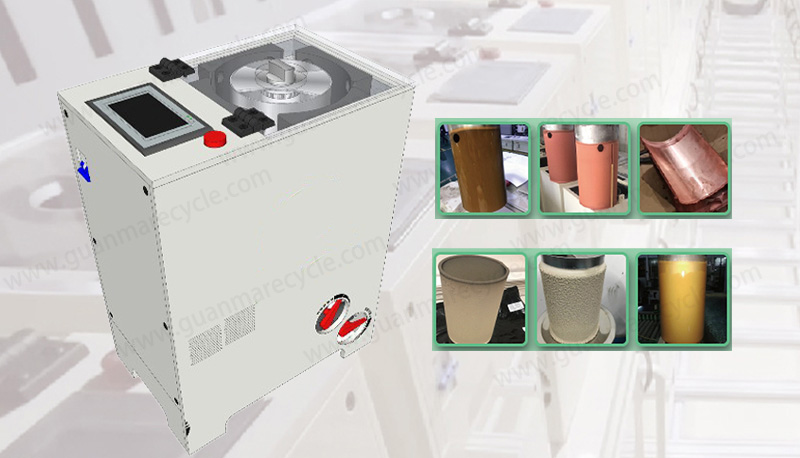

Use structure and principle

This machine consists of motor,hydraulic system,extracting hook,extracting mouth,main machine farme etc.The basic work principle is:the motor drives the hydraulic system and oil cyclinder, the hook is welded on the draw bar of the cylinder.the reciprocating movement of the oil pump and oil cylinder will cause the hook reciprocation.

Put the tire onto the hook mouth,extend the hook out of the mouth and hook onto the tire lip,the start the motor.Owing to the strong extracting force of the oil cylinder,the wire cable will be taken out as a whole ring.

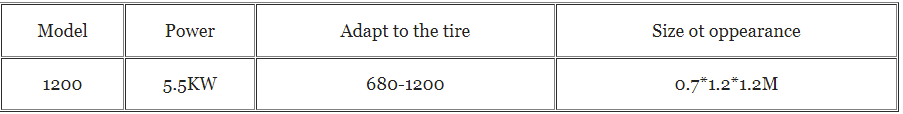

Tyre cutter

Application:to cut the tyre into sections at any length.It can be applied to cut any kind of rubber tyres.Structure and work theory It is consists of motor,hydraulic system,oil cylinder,a pair of knife,machine shelf,and driven mechanism.Its work theory is as the following:the motor drives the hydraulic system and oil cylinder,put the tyre between the knives,the start the cutting knifes to form a scissors to cut off the tyres.

Characteristics

This machine adopts big knife to make a easy cutting,high speed,low power consumption,small in size,and very convenient in movement.By the application of hydraulic system,the operation becomes very convenient and safe.

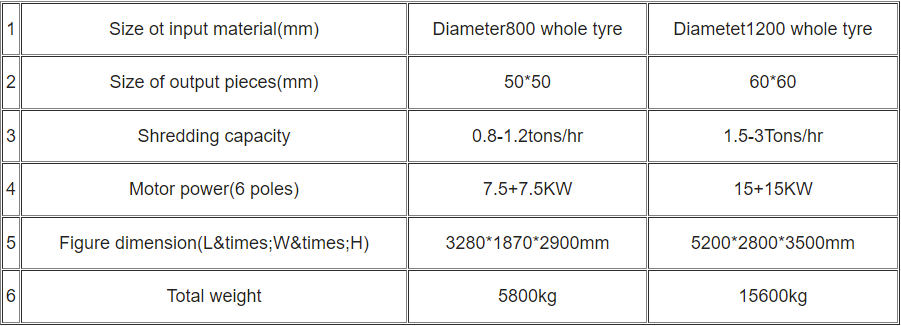

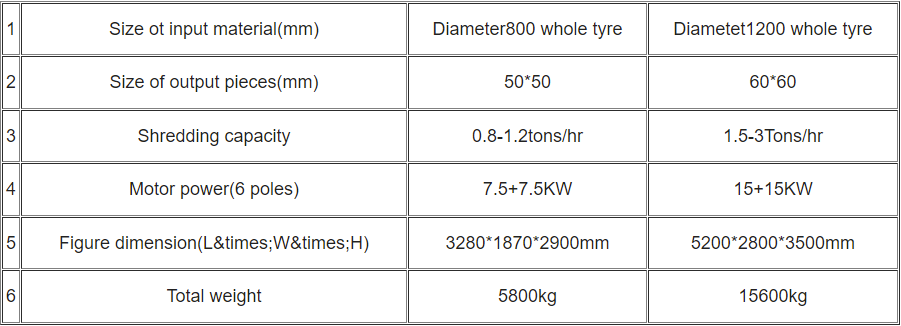

whole tyre crusher

Application:

This machine adopts a Germany technology.It crushes a whole tyre into the lumps at the size of 3~8cm directly,which will be ready for the shredding into the rubber powder at the size of 10~30 meshes and separating the wire pieces and fibers.

Characteristic

This machine possesses such features as compact structure,advanced technology,low energy onsumption,high efficiency etc.The crushing room adopts split structure,which is verycon venient to maintenance.The machine adopts hard alloy steel as its blade,high rigidity and wearable.It could be re-used by sharpening for extending the service lifetime.

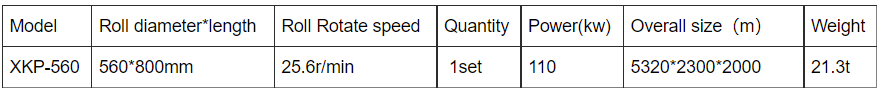

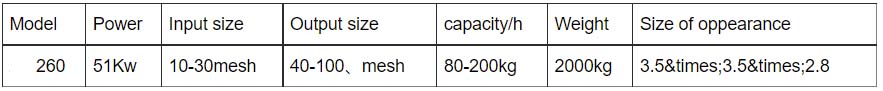

Rubber powder mill 560

Primarily pulverizing mill for crushing waste tires conducted at ambient temperature. Having a coarse pulverization, fine pulverization, and function of the isolated steel wire, etc..

The the material crushing effect of wire moles ideal. This machine adopts rotary milling works , material particles a performance of 10-30 mesh, screening, conveying pure colloidal particles can reach about 99% of the magnetic separator. Such as the need 40-100 purposes crumb, about 30 mesh particles directly ultrafine mill group processing.

800 sieves

800 sieve is a special rubber sieve that should be work together with the rubber shredders.It characteristics as good out-looking,low noise,high intensity,and low errors;It is widely used by rubber powder factories for grading the rubber powders.

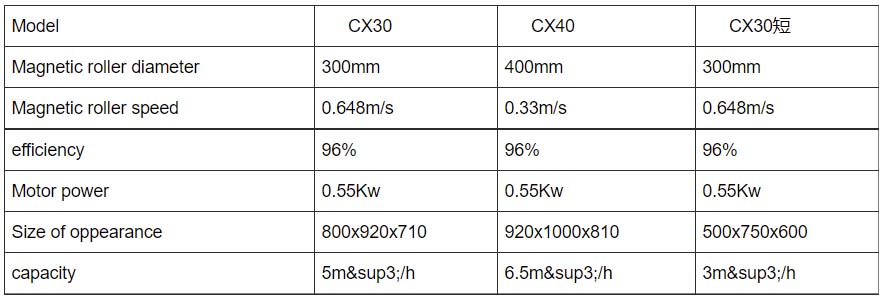

Model MS30 Magnetic separator

It works by the theory of permanent magnetism rollers.It is widely used for separating the foreign metal matters from such materil of rubber powder,coal powder,construction material,glass material etc.

It improves the material quality obviously by separation the mini metal powders.

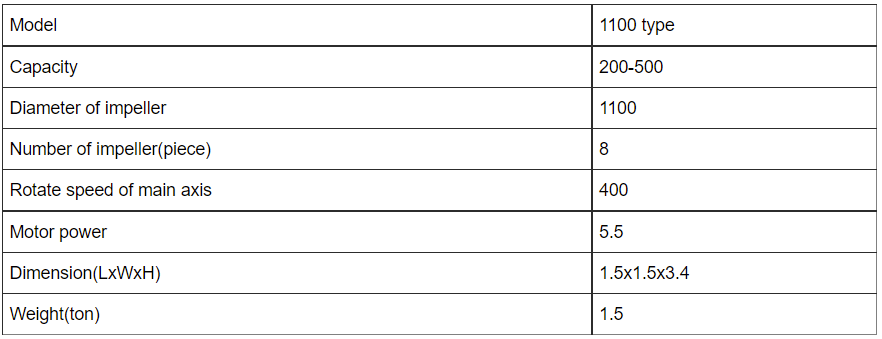

Fiber separator

It is a newly designed air separation equipment with good working performance and is suitable for separating microfiber flakes from rubber powder to improve its quality. It can also be used for the clarification of powdery materials in other chemical industries.

It is applied to produce the super fine rubber powder at the size of 40-100 meshes.Structure and work theory This unit consists of two or three sets of pulverizer, whirl wind collection,and electric devices.The main machine consists of machine shelf,main motor,step less variable speed motor,material feeding,and adjust ment mechanism,and a pair of movable disk and stationary disk.The basis work theory is the two disks move relatively,when the rubber come between them,it will be pulvenized.For guaranteeing the rubber power quality,the machine is cooled by water or wind.The material feeding is controlled by step less motor,so,the speed could be controlled accordingly to guarantee the wanted quality and capacity.The final powder is collected by whirl wind collector.There isn’t any dust in the whole process.

Small figure,low noise,high production capacity,low power consumption,easy operation,convenient maintenance ,and no pollution.The rubber powder is even in size and with burr surface,which would be a good condition to combine with other material.

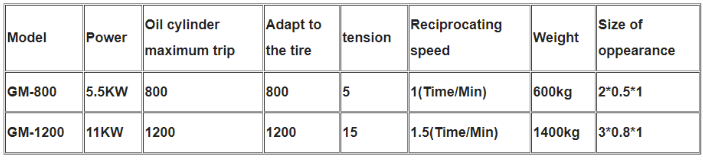

Technical Parameter

Product Advantages

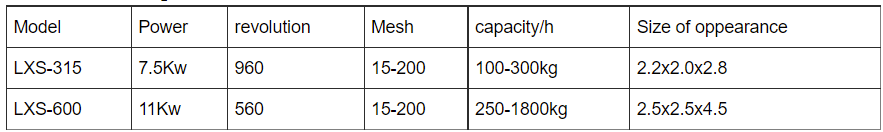

LXS-315 centrifugal sieve

Structure and principle

This machine is consists of machine shelf,centrifugal sieve,whirl wind separator,and motor.The material is feed via the hopper loader,then go to the centrifugal sieve,under the effect of centrifugal force,the material will go through the filter to reach the purpose of clarifying.The user can choose any size of the filter as per the market requirement of the powder sizes.This machine has such advantages of small figure,no noise,no vibration,low power consumption,easy maintenance,and easy operation.

22-I Crusher

This machine is applied to crushing such material as rubbers,plastics,chemical material,herbs etc.Structure and principle Structures:The knife of this machine is made of high quality alloy,it is very durable.This machine can be applied to crush many kinds of hard materials.By the rotation of rotary knives,the material will be cut off between the rotary knives and stationary knives.The size of the final particle will be controlled by the size of filter.It can produce any size of rubber particles by changing the filter sizes.

To guarantee the material quality,this machine is equipped with water cooling or wind cooling to make sure the material is crushed at a normal temperature.

800 Strong shaker

The rubber powder are widely used and almost covers all industrial fields. It can replace the material such as plastic and PVC, instead of nature rubber, be rebirth tires .It is used in sport runway and shoe soles, it also can be used to highway, air trip as well as third generation railway sleeper as modification asphalt and so on.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)