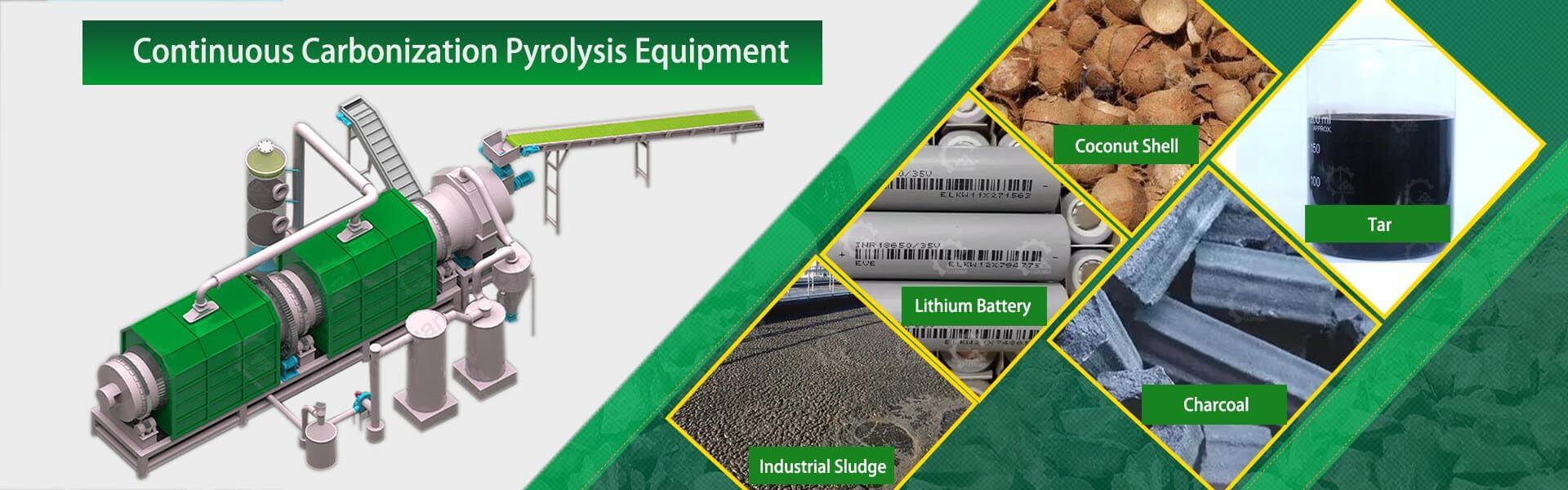

Home » Tyre Pyrolysis Plant

Tyre Pyrolysis Plant

Tyre Pyrolysis Plant can convert old tyre/rubber/plastic into useful products which may then be sold. A number of these useful products include carbon black, fuel oil, steel wire, and hydrocarb on gas. In the whole prod

Product Description

Tyre pyrolysis plants can convert old tyre/rubber/plastic into useful products which may then be sold. A number of these useful products include carbon black, fuel oil, steel wire, and hydrocarbon gas. In the whole production process, there is no black smoke, no bad smell. pyrolysis tyre recycling plant is undoubtedly an environmentally-friendly machine. So, it is smart to purchase a waste pyrolysis plant to recycle waste tyres. This can help you make huge profits while clearing the pile of old tyres you possess.

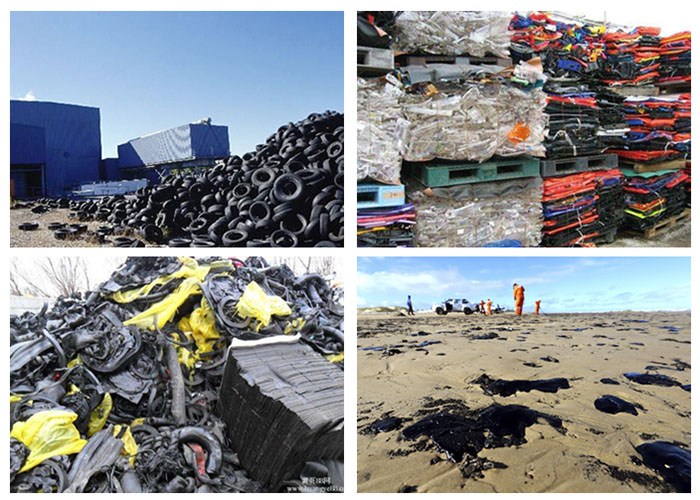

Raw Material

Waste Tires: mechanical tires, bicycle tires, motorcycle tires and other tires.

Waste Rubber: waste cable jackets, rubber soles, rubber gloves, seals, etc.

Plastic: waste acrylic (PMMA), PE, PP.

Sludge Oil: sewage sludge, oil mud, oil sludge, etc,.

NOTE: Different raw materials have different oil yields, Please contact GuanMa for details.

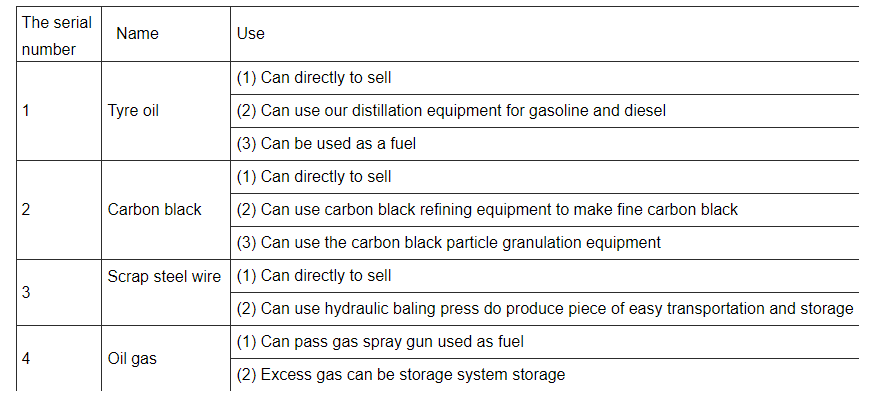

Final Product

As previously mentioned, pyrolysis machines produce black carbon powder, pyrolysis oil, and steel wire. These end products may be sold to industries for big profits. Pyrolysis oil, for instance, could be used to fuel industrial material burning machines. With further refinement inside a distillation machine, the oil can be changed into diesel or gasoline and employed to power also varieties of machinery. Black carbon powder could also be used as fuel, yet it is commonly together with clay and converted into construction bricks. The steel wire produced cab be reprocessed or changed into steel and iron rod.

Flow Chart

1. Feed raw material ( Tyre, Plastic, Rubber, oil sludge) into reactor by full-automatic feeding machine.

Note: Before the tire enters the reactor, if the tire is shredded by the BESTON tire crusher, a higher quality fuel oil will be obtained.

2. The reactor will be slowly heated, the oil gas will be formed.

3. The oil gas coming out from the reactor then goes to condensing system and becomes liquid oil. We adopt new-type condenser which can improve the oil yield efficiency and make the oil yield to the maximum.

4. The gas which can’t be liquefied under normal pressure will be designed to go back to combustion system through safety device. It can be recycled to heat the reactor as fuel, which will save energy for the whole working process.

5. The carbon black are discharged automatically while the waste materials are fed into reactor.

Product Advantages

1. No black smoke and no peculiar smell during pyrolysis

2. Environment friendly, high oil outup rate

3. Can convert wastes into fuel oil

4. Easily achieve high economic benefits

5. Easy to operate and maintain

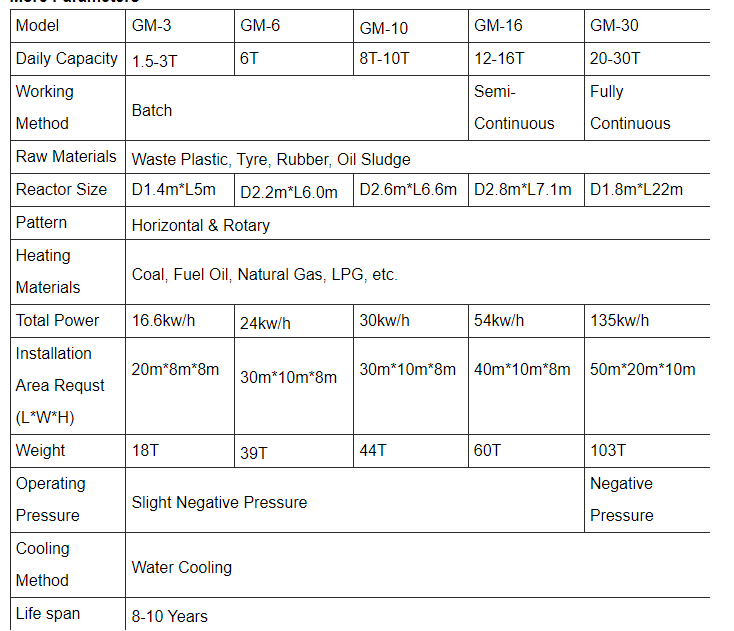

Technical Parameter

Related Products

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)