As the global demand for electric vehicles (EVs) and renewable energy storage continues to surge, the importance of efficient and sustainable battery recycling has become increasingly apparent. China, a leader in the production and consumption of lithium-ion batteries, has taken significant steps to develop a robust infrastructure for battery recycling. This article provides an in-depth look at the lithium-ion battery recycling plants in China, highlighting their capabilities, technologies, and the broader implications for the industry.

Overview of the Lithium-Ion Battery Recycling Market in China

China is home to some of the world’s lithium-ion battery recycling plants. The country’s rapid adoption of electric vehicles and the growing emphasis on environmental sustainability have driven the development of this sector. According to recent battery recycling reports, China is expected to dominate the global lithium-ion battery recycling market in the coming years, thanks to its extensive manufacturing capabilities and supportive government policies.

Technologies Used in Lithium-Ion Battery Recycling Plants

Lithium-ion battery recycling plants in China employ a variety of technologies to maximize the recovery of valuable metals. Some of the key technologies include:

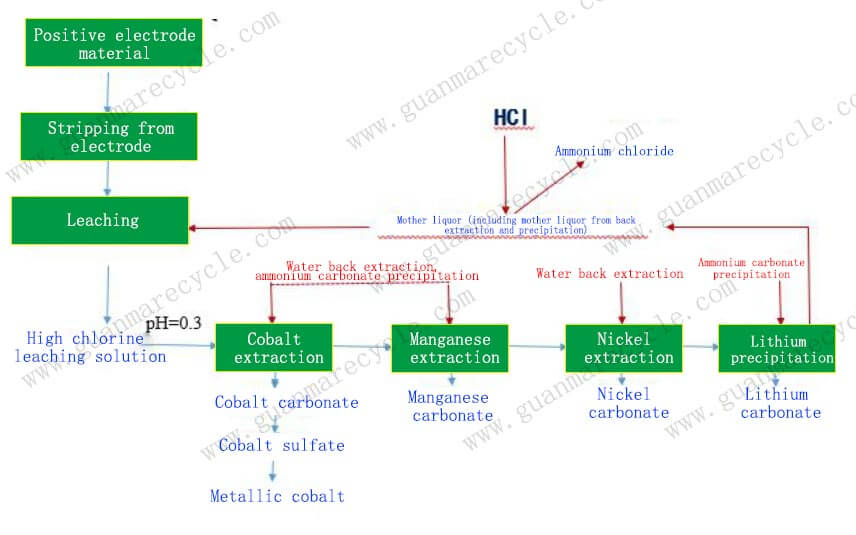

1. Hydrometallurgy

This process involves using chemical solutions to dissolve and separate the metals from the battery materials. It is highly effective in recovering lithium, nickel, cobalt, and manganese. Hydrometallurgical processes are favored for their ability to achieve high purity levels of the recovered metals.

2. Pyrometallurgy

Pyrometallurgical processes involve high-temperature treatments to smelt and extract the metals. This method is particularly useful for processing large volumes of batteries and can handle a wide range of battery chemistries.

3.Direct Recycling

Also known as physical recycling, this method focuses on reusing the battery components without breaking them down completely. Direct recycling can preserve the structure and properties of the battery materials, making it a promising approach for sustainable battery management.

4. Mechanical Processes

Mechanical processes such as shredding, sieving, and magnetic separation are used to break down the batteries and separate the different components. These processes are often combined with hydrometallurgy or pyrometallurgy to achieve higher recovery rates.

Environmental and Economic Benefits

The development of lithium-ion battery recycling plants in China offers several environmental and economic benefits:

1. Resource Conservation

Recycling lithium-ion batteries helps conserve natural resources by reducing the need for virgin materials. This is particularly important for metals like cobalt and lithium, which are finite and often sourced from environmentally sensitive regions.

2. Waste Reduction

By recycling spent batteries, the amount of waste sent to landfills is significantly reduced. This helps mitigate the environmental impact of battery disposal and supports a circular economy.

3. Economic Value

The recovery of valuable metals from spent batteries creates economic value. Lithium, nickel, cobalt, and manganese are in high demand, and their prices can fluctuate based on market conditions. Recycling these metals provides a stable and cost-effective supply chain.International Collaboration: Collaborating with international partners can facilitate the exchange of knowledge and best practices, helping to advance the global battery recycling industry.

Lithium-ion battery recycling plants in China are at the forefront of a rapidly growing industry, driven by the increasing demand for electric vehicles and the need for sustainable resource management. These plants employ advanced technologies to recover valuable metals such as lithium, nickel, cobalt, and manganese, offering significant environmental and economic benefits. As the industry continues to evolve, addressing technical barriers, regulatory challenges, and public awareness will be key to realizing the full potential of battery recycling.

If you are looking to invest in or partner with a lithium-ion battery recycling plant in China, consider the expertise and capabilities of leading companies like GuanMa Mchinery lithium battery recycling plant. For more information or to discuss potential collaborations, feel free to contact us. Our team is dedicated to providing comprehensive support and ensuring a successful and sustainable partnership in the battery recycling sector.