Lithium-ion battery recycling using hydrometallurgy recycling is a highly efficient and environmentally friendly method for recovering valuable metals such as lithium, cobalt, and nickel.

What is Hydrometallurgy?

Hydrometallurgy is a technique that uses aqueous solutions and chemical reagents to extract and purify metals from their ores or waste materials. In the context of lithium-ion battery recycling, hydrometallurgy involves the use of leaching agents to dissolve the metals from the battery materials, followed by a series of chemical processes to recover and purify them.

Steps in Hydrometallurgical Recycling

1. Pre-Treatment

Disassembly: The first step is to disassemble the batteries to separate the electrodes and other components.

Shredding and Crushing: The battery cells are then shredded and crushed to increase the surface area for better leaching.

2. Leaching

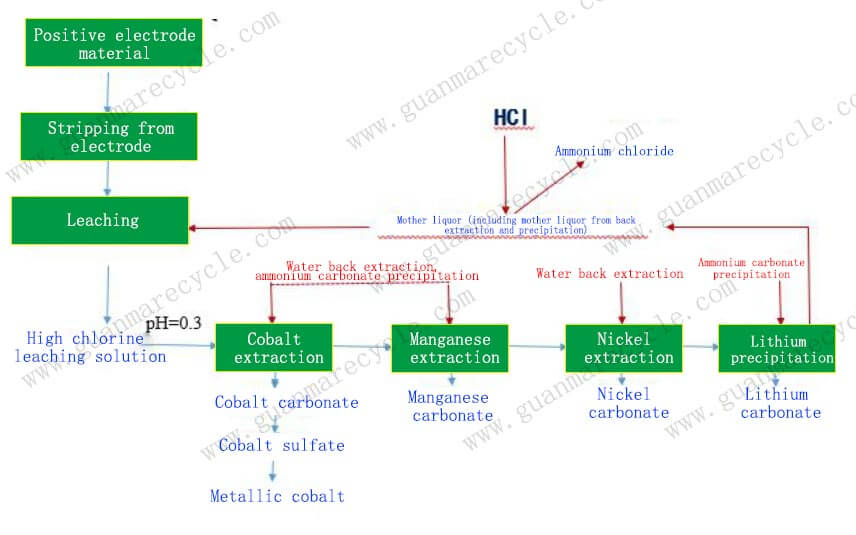

Acidic or Alkaline Leaching: The crushed material is treated with acidic or alkaline solutions to dissolve the metals. Common leaching agents include sulfuric acid, hydrochloric acid, and sodium hydroxide.

Selective Leaching: Different metals can be selectively leached by adjusting the pH and using specific reagents, ensuring high recovery rates and purity.

3. Purification and Recovery

Solvent Extraction: The leachate is processed through solvent extraction to separate and concentrate the metals.

Precipitation and Filtration: Metals are precipitated out of the solution and filtered to obtain solid metal compounds.

Electrowinning: For some metals, electrowinning is used to deposit pure metal from the solution onto a cathode.

Benefits of Hydrometallurgical Recycling

High Recovery Rates: Hydrometallurgy can achieve high recovery rates of valuable metals, often exceeding 90%.

Environmental Sustainability: This method minimizes the environmental impact by reducing the need for primary mining and preventing the disposal of hazardous waste.

Economic Viability: The recovered metals can be sold back into the market, creating a circular economy and generating significant economic value.

Applications and Future Prospects

Battery Manufacturing: The recovered metals can be reused in the production of new lithium-ion batteries, reducing the reliance on virgin materials.

Other Industries: The metals can also be used in various other industries, such as electronics, aerospace, and automotive.

Conclusion

Hydrometallurgy Recycling is a key technology in the sustainable recycling of lithium-ion batteries. By efficiently recovering valuable metals, this method not only addresses the growing issue of battery waste but also supports a more circular and environmentally friendly economy. For more information on hydrometallurgical recycling or to discuss potential solutions for your specific needs, feel free to contact us. Our team of experts is here to provide comprehensive support and ensure a successful and sustainable recycling operation.