Comparison of Processing Technologies for Spent Lithium Iron Phosphate Batteries

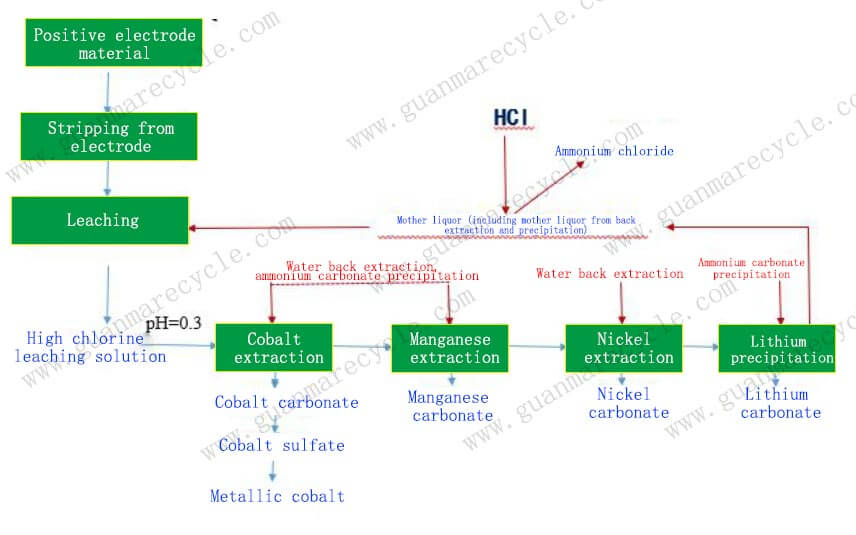

The processing technologies for spent lithium iron phosphate (LFP) batteries mainly include hydrometallurgical recovery, pyrometallurgical recovery, and bioleaching recovery techniques. pyrometallurgical Recovery Technology pyrometallurgical recovery technology is simple in principle and does not require sophisticated equipment. However, it has high energy consumption, low metal recovery rates from spent batteries, and can easily cause environmental pollution […]

Comparison of Processing Technologies for Spent Lithium Iron Phosphate Batteries Read More »