How to Recycle Iron Can NCM Batteries? As the global shift towards renewable energy sources continues to accelerate, the demand for lithium-ion batteries, including Iron Can NCM (Nickel Cobalt Manganese) batteries, is growing exponentially. This surge in usage has also led to an increased focus on sustainable practices for lithium battery disposal and lithium ion battery recycling. In this article, we will delve into the process of recycling Iron Can NCM batteries, exploring the methods used to recover valuable metals and the costs involved in setting up a lithium battery recycling plant.

Understanding Iron Can NCM Batteries

Iron Can NCM batteries are a type of lithium-ion battery characterized by their robust iron casing and the use of Nickel, Cobalt, and Manganese in their cathode material. These batteries are known for their high energy density and stability, making them ideal for various applications, including electric vehicles and energy storage systems.

The Importance of Recycling Iron Can NCM Batteries

Economic Benefits

The recovered metals can be reused in the manufacturing of new batteries, reducing the need for virgin materials and lowering production costs.

The Recycling Process for Iron Can NCM Batteries

The recycling process for Iron Can NCM batteries typically involves several key steps:

1. Collection and Discharge: Used batteries are collected and safely discharged to prevent any potential hazards.

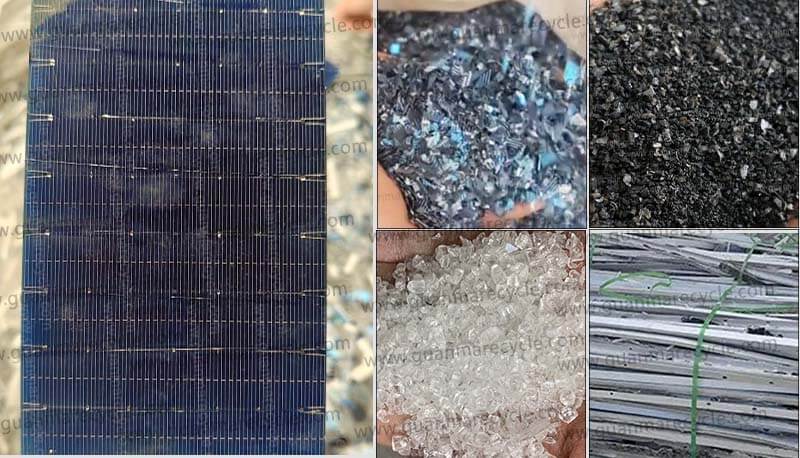

2. Pre-treatment: Batteries undergo shredding or crushing to separate the metallic components from the non-metallic ones.

3. Metal Recovery: Various techniques, such as pyrometallurgy and hydrometallurgy, are employed to extract and purify the metals.

4. Refinement: The recovered metals are further refined to meet the purity standards required for reuse.

Cost Considerations for Setting Up a Lithium Battery Recycling Plant

The cost of setting up a lithium battery recycling plant can vary significantly depending on several factors:

1. Scale and Capacity

The size and capacity of the plant directly influence the initial investment. Larger plants with higher throughput require more substantial upfront costs.

2. Technology and Automation

Advanced technologies and higher levels of automation can increase the efficiency of the recycling process but also increase the lithium battery recycling plant cost.

3. Location and Infrastructure

The location of the plant and existing infrastructure, such as access to utilities and transportation networks, can affect the total cost.

4. Regulatory Compliance

Meeting environmental regulations and obtaining necessary permits can add to the overall expense.

GuanMa Machinery is a leading provider of lithium battery recycling solutions, offering comprehensive systems designed to efficiently recycle Iron Can NCM batteries. Their expertise in the field includes customizing recycling plants to meet specific needs, ensuring optimal recovery rates and minimal environmental impact.

Recycling Iron Can NCM batteries is not only essential for environmental sustainability but also offers significant economic benefits. By understanding the process and considering the lithium battery recycling plant cost, businesses can make informed decisions that align with both their financial objectives and their commitment to sustainability.