The processing technologies for spent lithium iron phosphate (LFP) batteries mainly include hydrometallurgical recovery, pyrometallurgical recovery, and bioleaching recovery techniques.

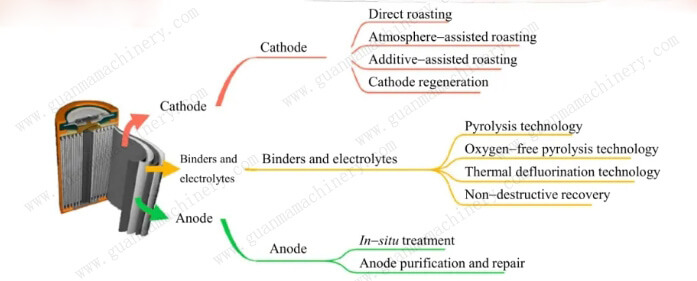

pyrometallurgical Recovery Technology

pyrometallurgical recovery technology is simple in principle and does not require sophisticated equipment. However, it has high energy consumption, low metal recovery rates from spent batteries, and can easily cause environmental pollution during the recovery process.

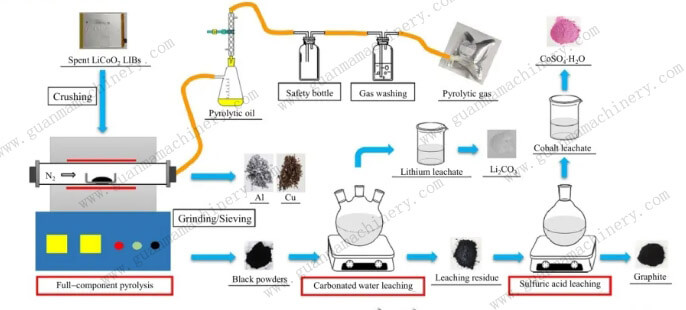

Hydrometallurgical Recovery Technology

Hydrometallurgical recovery technology is relatively mature and results in high-purity recovered metals. It enables targeted recovery of metals from spent batteries. The disadvantages include a longer process flow, higher energy consumption, higher costs, and stringent equipment requirements. Additionally, it cannot effectively recover organic substances such as electrolytes from the batteries.

Bioleaching Recovery Technology

Bioleaching technology has the advantages of being a simple and environmentally friendly process that does not require sophisticated equipment. However, the technology is still immature, has a long processing cycle, difficult control of leaching conditions, and low recovery rates. Other recovery technologies are currently in the experimental phase.

In summary, the recycling of spent lithium iron phosphate batteries will continue to be dominated by hydrometallurgical recovery technology, with some advancements in bioleaching. Optimizations across multiple aspects will eventually lead to more efficient and effective recycling processes.