In this guide, we will explore the factors that influence the lithium ion battery recycling machine price, as well as the benefits and considerations when choosing a battery recycling plant. In today’s rapidly evolving technological landscape, the demand for lithium-ion batteries has skyrocketed. This surge in usage has led to a parallel increase in the need for efficient lithium ion battery recycling processes. As the global push towards sustainability gains momentum, businesses and individuals alike are looking for cost-effective solutions to manage lithium battery waste disposal.

Understanding the Lithium Batteries Recycling Process

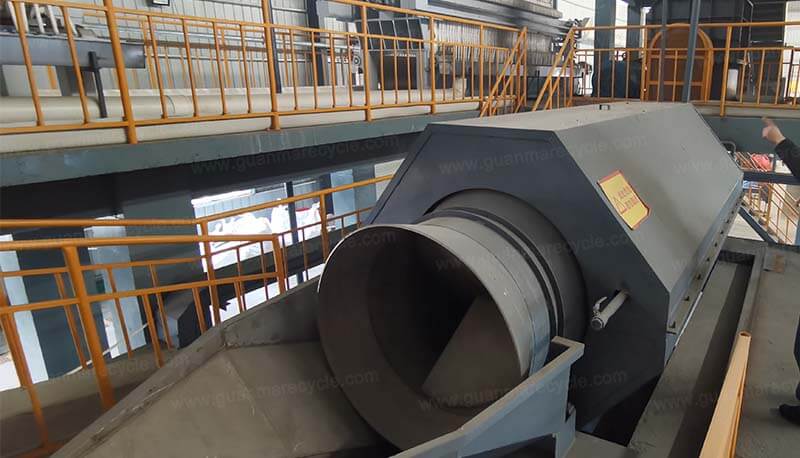

Before diving into the specifics of lithium ion battery recycling machine, it’s important to understand how these machines operate. The lithium batteries recycling process typically involves several key steps:

1. Collection and Discharge: Used batteries are collected and safely discharged to prevent any potential hazards.

2. Shredding and Separation: The batteries are shredded, and valuable materials like lithium, cobalt, nickel, and manganese are separated from other waste.

3. Recovery and Refinement: Recovered materials are refined and prepared for reuse in new batteries or other applications.

Each step requires specialized equipment, which can vary widely in terms of cost and efficiency.

Factors Influencing Lithium Ion Battery Recycling Machine Price

1. Capacity and Throughput

The capacity of a lithium battery recycling machine plays a crucial role in determining its price. Machines capable of handling larger volumes of batteries tend to be more expensive but offer better long-term value through increased throughput.

2. Technology and Automation Level

Advanced technology and higher levels of automation can significantly impact the lithium ion battery recycling machine cost. Automated systems reduce labor costs and improve safety, but they come with a higher upfront investment.

3. Brand and Quality

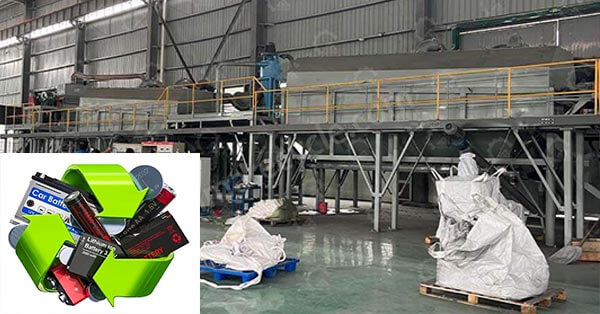

Just like any other machinery, the brand and quality of a lithium ion battery recycling machine affect its price. Well-established manufacturers such as GuanMa Machinery are known for their reliability and longevity, which can justify a higher price tag.

4. Additional Features and Customization

Customized machines designed to meet specific needs can be more expensive than standard models. Additional features like enhanced safety measures or advanced material separation capabilities also add to the cost.

Choosing the Right Battery Recycling Plant

When selecting a battery recycling plant, consider not only the lithium ion battery recycling machine price but also the overall efficiency and environmental impact of the system. An effective recycling plant should:

Offer a high return on investment through cost savings on raw materials.

Minimize environmental footprint by adhering to strict waste management protocols.

Provide a scalable solution that can adapt to changing market demands.

Investing in a reliable and efficient lithium battery recycling machine from a reputable manufacturer like GuanMa Machinery ensures that you are making a sustainable choice that aligns with both economic and environmental goals.

The lithium ion battery recycling machine price is just one aspect to consider when entering the recycling industry. By focusing on the quality, efficiency, and environmental impact of your chosen solution, you can ensure that your investment will yield long-term benefits.