Project Overview:

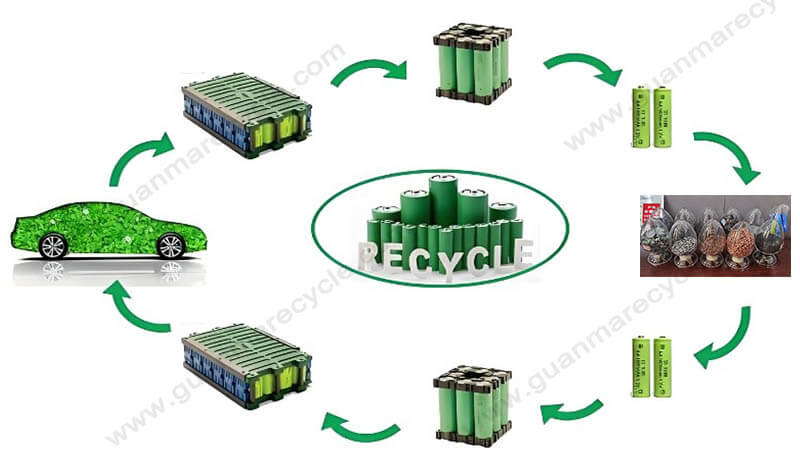

Material for Processing: Ternary lithium battery

Processing Capacity: 800-1000 kg/h Hydrometallurgical battery recycling production line

Solution Provided:

Hydrometallurgy battery recycling employs aqueous chemical processes to recover valuable metals (e.g., lithium, cobalt, nickel) from spent batteries. Through leaching, extraction, and precipitation, materials are dissolved and purified for high-efficiency resource recirculation, reducing reliance on primary mining and mitigating battery waste environmental impact. This eco-friendly approach is pivotal for sustainable development amid escalating global battery demands.

Collaboration Process:

Following multiple rounds of technical discussions and on-site demonstrations, the client expressed satisfaction with the hydrometallurgical battery recycling production line. This positive feedback led to the signing of the procurement contract. Subsequently, we arranged for shipment and dispatched a team of engineers to the client’s site for installation and commissioning, ensuring a seamless start-up of operations.

This project in South Korea stands as a testament to our capability in delivering efficient and eco-conscious recycling infrastructure to meet the demands of a greener future.