In the ever-evolving landscape of sustainable technology, Guanma Machinery presents an innovative solution for recycling precious metals from spent Iron Can NCM (Nickel Cobalt Manganese) and NCA (Nickel Cobalt Aluminum) lithium-ion batteries. Our equipment is meticulously designed to recover valuable metals such as nickel, cobalt, and aluminum, thus contributing significantly to the global circular economy.

The process begins with state-of-the-art disassembly techniques that safely dismantle the iron can housing without causing environmental harm or loss of valuable content. The machinery then proceeds to crush and separate the battery components efficiently, isolating the metal compounds present in NCM and NCA cathodes.

Guanma Machinery proprietary recycling technology employs a combination of hydrometallurgical and pyrometallurgical processes to extract these precious metals with high purity and yield. This method ensures that the embedded metals are recovered in their purest form, ready for reuse in the production of new batteries.

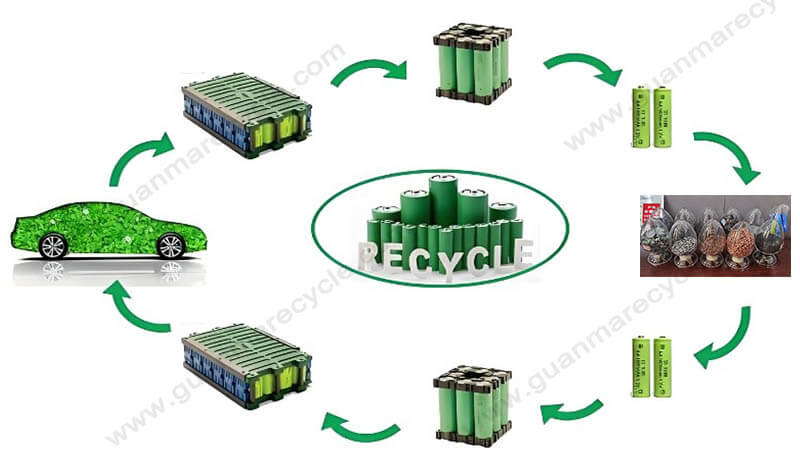

This closed-loop system not only minimizes waste but also reduces the dependence on mining virgin materials, thereby lowering the overall carbon footprint and conserving natural resources. It’s a testament to our commitment towards environmental stewardship and sustainable industrial practices.

In essence, our lithium-ion battery recycling equipment empowers businesses worldwide to transform what was once considered waste into a valuable resource. By choosing Crown Horse Machinery, industries can contribute effectively to the recycling ecosystem while harnessing the true potential of finite resources within used Iron Can NCM and NCA batteries.

Thus, we stand at the forefront of revolutionizing precious metals recovery, turning the end of one lifecycle into the beginning of another – all through cutting-edge, eco-friendly technology that sets a new standard for sustainability in the battery recycling industry.