In the quest for sustainable energy solutions, the efficient extraction of lithium from spent pouch LFP (Lithium Iron Phosphate) batteries has become a critical focus area. As demand for electric vehicles and renewable energy storage systems soars, so does the necessity for robust recycling methods to recover valuable materials like lithium. This article delves into the latest advancements in recycling technology, detailing the equipment, processes, and pricing that are reshaping the industry.

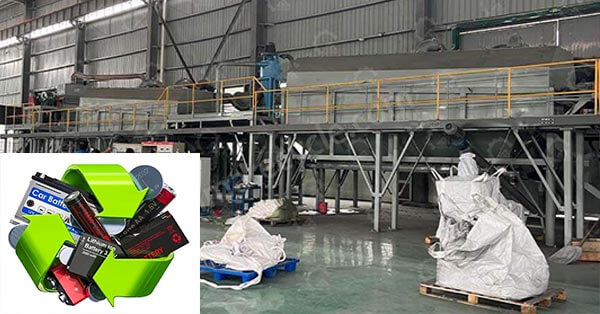

State-of-the-Art Equipment for Pouch LFP Battery Recycling

Specialized recycling equipment is pivotal in the processing of pouch LFP batteries. These machines are designed to safely dismantle and shred the batteries before separating the components through a series of automated steps.

Key features include

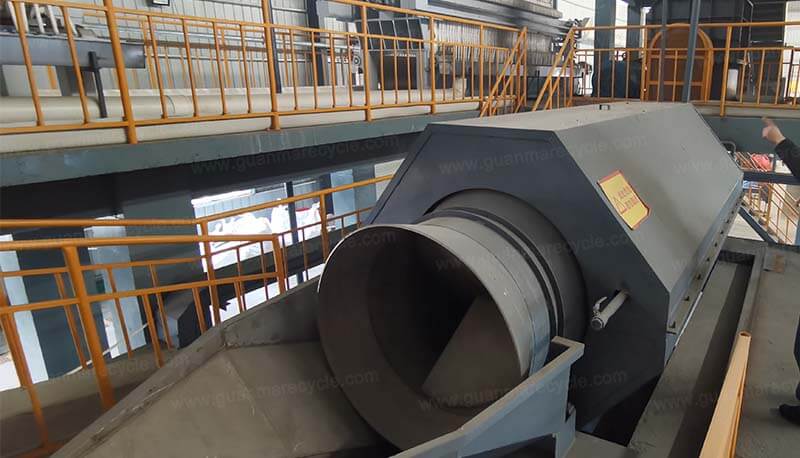

Shredding Units

Capable of reducing batteries to manageable pieces while minimizing the risk of fire or release of hazardous substances.

Separator Systems

Utilizing advanced techniques such as magnetic separation, air classification, and electrostatic separation to isolate lithium and other metals.

Refining Equipment

Refines the extracted lithium to high purity levels suitable for reuse in new batteries.

The recycling process involves several stages designed to maximize lithium recovery while minimizing environmental impact:

1. Pre-Treatment

Batteries are discharged and mechanically shredded.

2. Physical Separation

Components are separated based on physical properties.

3. Chemical Recovery

Lithium and other metals are extracted using chemical processes.

4. Refinement and Purification

Recovered lithium undergoes further processing to achieve high-grade purity.

Pricing and Cost Considerations

The cost of recycling pouch LFP batteries can vary depending on factors such as the scale of operation, the efficiency of the equipment, and the current market price of lithium. Typically, larger volumes can benefit from economies of scale, making the per-unit cost of recycling lower. It’s essential to consider both the initial investment in recycling equipment and ongoing operational expenses.

Streamlining the Recycling Process

To make the process more attractive to potential investors and operators, manufacturers are continually optimizing their equipment and refining their processes to:

Reduce energy consumption during recycling.

Minimize waste and environmental impact.

Increase the speed and throughput of the recycling line.

Enhance the purity and recovery rate of lithium and other metals.

The Future of Lithium Extraction from Pouch LFP Batteries

As the technology for extracting lithium from pouch LFP batteries continues to evolve, it promises not only economic benefits but also significant environmental advantages. By investing in the right equipment and processes, companies can secure a sustainable supply of lithium, contributing to the circular economy and supporting the transition to renewable energy sources.

For those interested in entering the lithium recycling market, now is an opportune time to explore the available options, compare equipment capabilities, and assess the total cost of ownership.