As the global solar industry expands, so does the challenge of managing end-of-life solar panels. If you’re seeking to process solar panel waste, our solar panel recycling equipment offers tailored solutions for your specific needs.

How Are Solar Panels Recycled? A Step-by-Step Breakdown

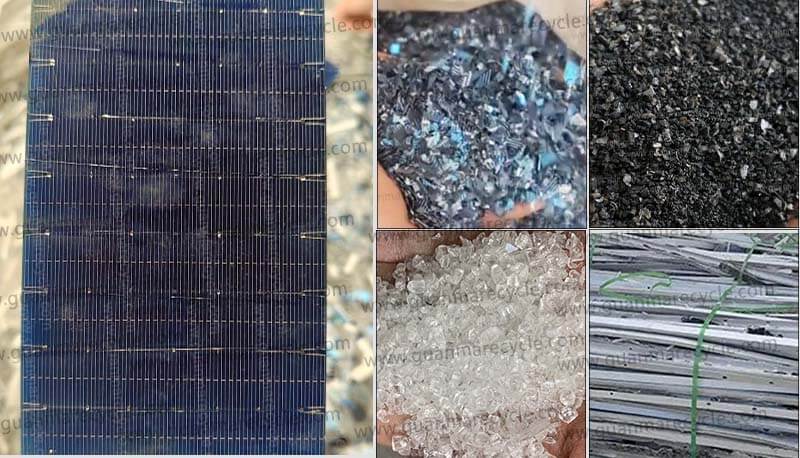

Solar panels consist of glass (75% by weight), aluminum frames, silicon cells, and trace metals like silver and copper. Recycling involves:

1. Mechanical Shredding: High-powered shredders break panels into smaller pieces, separating aluminum frames with 99% efficiency.

2. Thermal & Chemical Separation: Heating to 500°C evaporates adhesives, while electrostatic sorters and acid leaching isolate silicon wafers and metals.

3. Material Recovery:

Glass: 85–95% recovered for new panels or construction.

Aluminum: 98% purity achieved for reuse in manufacturing.

Silicon: Up to 95% recycled, with 45% purity for photovoltaic applications.

Precious Metals: Silver and copper extracted with 95% recovery rates.

Tailored Solutions for Your Business Needs

1. Raw Materials Handled

Our equipment processes monocrystalline, polycrystalline, and thin-film solar panels, addressing the diverse composition of PV waste. For example:

Thin-film panels: Require specialized shredding and precipitation to recover cadmium and tellurium.

Silicon-based panels: Focus on separating glass, aluminum, and silicon cells through automated disassembly.

2. Scalable Processing Capacity

Choose from modular systems designed for:

Small-scale operations: 600–1,200 kg/hour for startups or regional recycling centers.

Large-scale facilities: Up to 1.5 tons/hour for industrial use, ensuring high throughput while maintaining 98% material purity.

3. Valuable End Products

Recycling yields market-ready materials:

Aluminum: Sold to automotive and construction industries.

Glass: Repurposed into new solar panels or consumer goods.

Silicon: Used in semiconductor manufacturing after purification.

Precious Metals: Silver and copper contribute to 14% of a panel’s material value.

Why Invest in Our Solar Panel Recycling Equipment?

1. Environmental Compliance: Meet EU WEEE Directive and IEC 62321-5 standards for sustainable recycling.

2. Economic Viability: Recover materials worth $450 million globally by 2030, offsetting operational costs.

3. Cutting-Edge Technology:

99% Material Recovery: Innovations like stainless steel ball abrasion ensure minimal waste.

Automated Sorting: AI-driven systems reduce manual labor and enhance precision.

Stay Ahead of the Curve

The solar panel recycling market is growing at a 7.4% CAGR, driven by stricter regulations and demand for circular economy practices. By adopting our equipment, you position your business as a leader in sustainable waste management while tapping into a $548 million market by 2030.

Take Action Today

Don’t let solar panel waste become a liability—transform it into a revenue stream. Our team of experts will design a customized recycling line to match your production goals. Contact us to learn how our solar panel recycling equipment can streamline your operations and contribute to a greener future.