Lead-acid batteries are a crucial part of our everyday lives, powering everything from vehicles to backup power supplies. But as with any resource, their disposal can have significant environmental impacts. Recycling lead-acid batteries isn’t just possible—it’s essential for the planet, the economy, and for managing valuable materials. In this article, we’ll explore how lead-acid batteries are recycled, why it matters, and the steps involved in the process.

What is a Lead-Acid Battery?

A lead-acid battery consists of two primary components: lead and sulfuric acid. These batteries are commonly used in cars, trucks, motorcycles, and even some backup power systems due to their reliability and affordability. Despite their widespread use, these batteries can be dangerous if disposed of improperly, releasing harmful chemicals and heavy metals into the environment.

Why Recycling Lead-Acid Batteries is Important

Recycling lead-acid batteries has profound environmental and economic benefits. First and foremost, improper disposal can cause lead contamination in soil and water. The lead, a toxic heavy metal, poses serious risks to both human and animal health. Additionally, sulfuric acid can pollute water sources. By recycling, we prevent these dangerous substances from harming the environment and conserve valuable resources like lead, which can be reused in new batteries.

How Lead-Acid Batteries Are Recycled

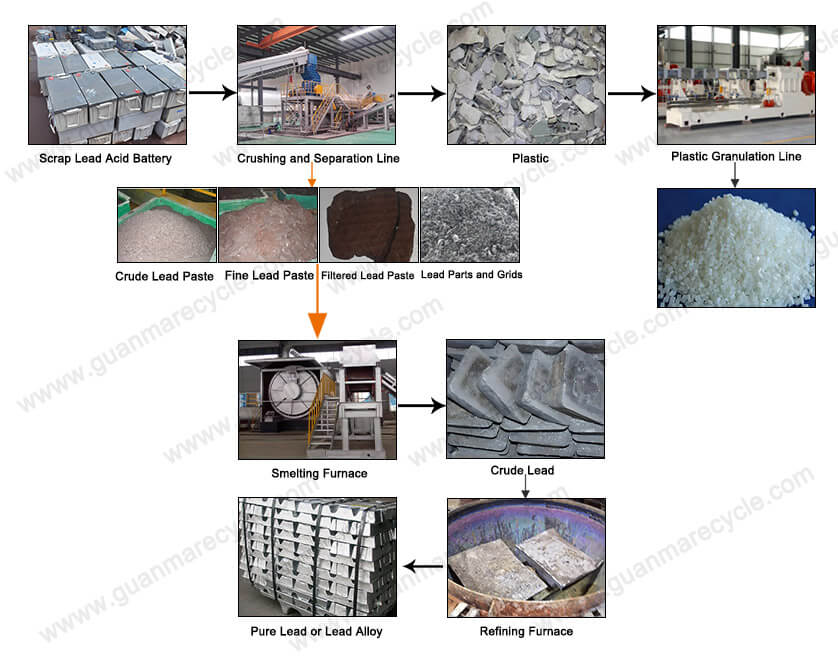

The process of recycling lead-acid batteries involves several crucial steps to ensure that the harmful components are safely removed and valuable materials are reused.

Collection and Transport: First, the used batteries are collected from various sources, including auto repair shops, recycling centers, and consumers.

Discharge and Removal of Acid: Before processing, the acid is neutralized and removed from the battery to prevent any leaks or spills.

Separation of Lead Components: The remaining parts of the battery, such as lead plates, are separated and cleaned.

Smelting: The lead is then smelted at high temperatures, turning it into a purified form that can be reused in the production of new batteries.

Sulfuric Acid Processing: The sulfuric acid can be neutralized and converted into water or used in the production of other products, such as fertilizers.

Methods of Recycling Lead-Acid Batteries

There are two main methods used to recycle lead-acid batteries: mechanical and chemical methods.

Mechanical Methods

This involves the physical breaking down of the battery to separate its components. Lead plates are removed, cleaned, and smelted. The plastic casing is also recycled.

Chemical Methods

Chemical methods involve the neutralization of sulfuric acid and breaking down other components using chemical reactions. This ensures that toxic substances are safely processed.

What Happens to the Recycled Materials?

The recycled materials from lead-acid batteries are repurposed into new products. Lead is used in the production of new batteries, and sulfuric acid can be neutralized to create water or used in industrial processes like fertilizer manufacturing.

Benefits of Lead-Acid Battery Recycling

The benefits of recycling lead-acid batteries are clear:

Reduced Pollution: Recycling prevents harmful chemicals from entering the environment.

Conservation of Resources: Reusing lead reduces the need for mining.

Job Creation: The recycling industry provides jobs and supports local economies.

Common Misconceptions About Recycling Lead-Acid Batteries

There are several myths surrounding the recycling of lead-acid batteries. One of the biggest misconceptions is that it’s dangerous to recycle these batteries. However, when handled properly, recycling is a safe and controlled process that significantly reduces environmental risks.

Conclusion

Lead-acid batteries are recyclable, and the recycling process is vital for reducing environmental harm and conserving valuable resources.