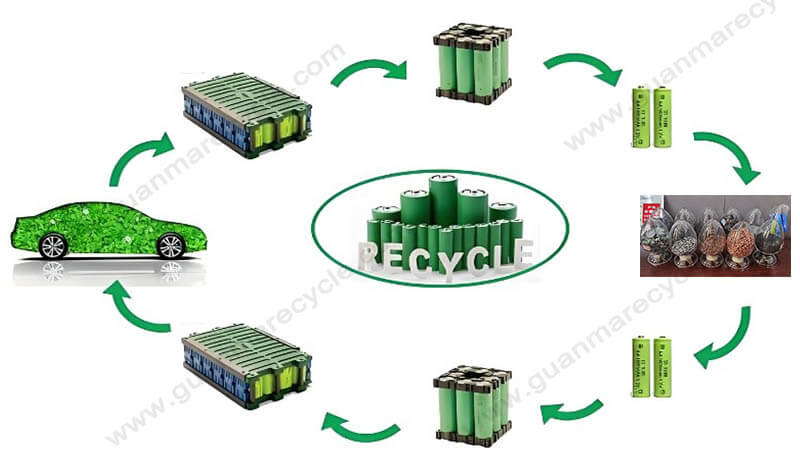

Guanma Machinery Battery Recycling Technology:

1. The process begins with the pretreatment of spent lithium-ion batteries, which includes discharging, dismantling, crushing, and sorting; after dismantling, the plastic and iron casings are recovered.

2. The sorted electrode materials undergo an alkali leaching, acid leaching, and purification process, followed by extraction; this extraction step is crucial as it separates copper from cobalt and nickel.

3. The extracted copper is then directed to an electrowinning cell where it is processed into an electrowon copper product.

4. After the extraction, the cobalt and nickel solutions undergo further separation, at which point they are crystallized and concentrated to directly produce cobalt salts and nickel salts.

5. Alternatively, the separated cobalt and nickel can be individually fed into electrowinning cells to yield electrowon cobalt and electrowon nickel products.

6. The recovery rates for cobalt, copper, and nickel through the electrowinning process reach up to 99%, with grades of 99.98% for cobalt, 99.95% for copper, and 99.2% to 99.9% for nickel. The final products, such as cobalt sulfate and nickel sulfate, meet relevant standards.