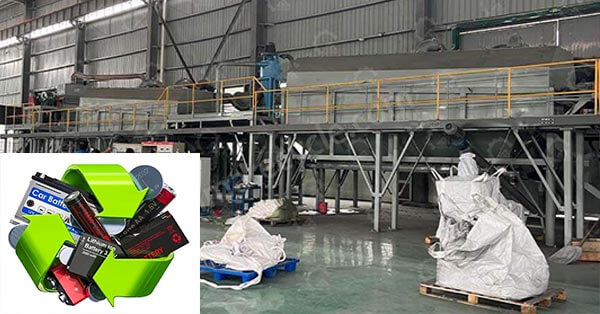

Diverse Raw Material Handling

Our pioneering Battery Recycling Process adeptly manages a wide array of battery types, encompassing lithium-ion, lead-acid, nickel-metal hydride, and more. From depleted EV batteries to portable electronics’ power cells, we transform waste into a wellspring of reusable resources.

Premium Outputs & Uncompromised Purity

Post-processing yields a treasure trove of metals: lithium, cobalt, nickel, lead, and copper, each refined to purity grades as high as 99.9%. These recovered metals are reintroduced into battery production and tech manufacturing, fueling a sustainable cycle of material use.

Comprehensive Recycling Procedure

Our workflow comprises meticulous stages:

Collection & Categorization

Batteries are gathered and classified according to chemistry.

Safe Disassembly

Automated systems dismantle batteries safely.

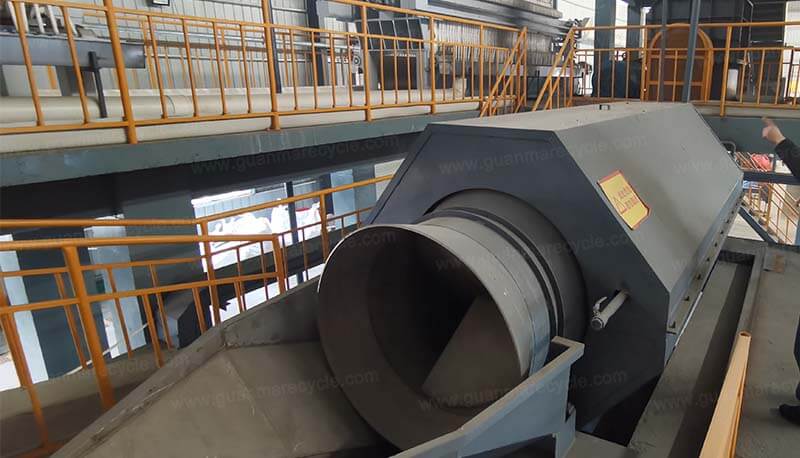

Mechanical Processing

Shredding breaks down components for efficient separation.

Chemical Extraction

Hydrometallurgical and pyrometallurgical techniques free metals from shredded materials.

Refining & Purification

Sophisticated methods ensure peak metal purity.

Material Recovery

Refined metals are readied for their next application.

Outstanding Process Benefits

Sustainability at Core

Reduces dependency on virgin materials, curbing environmental degradation and hazardous waste generation.

Optimized Resource Utilization

Enhances material recovery rates, promoting economic and environmental efficiency.

Circular Economy Champion

Bolsters a closed-loop system that perpetuates material flow within the industry.

Innovative & Adaptive

Continuously updated to handle emerging battery technologies, ensuring future-readiness.

By embracing our Battery Recycling Process, stakeholders actively contribute to a greener future, transforming waste into a catalyst for sustainable growth and innovation.